< Previous | Contents | Next >

Section 1 General

101. Application

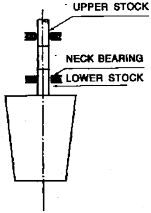

1. The requirements in this chapter apply to single plate rudders and double plate rudders of stream line section and ordinary shape, rudders having no bearing below the neck bearing, (refer to Fig 4.1.1).

2. Rudder other than those specified in Par 1, are to comply with the requirement in Pt 4, Ch 1 of

Rules for the Classification of Steel Ships.

3. Requirements not specified in this chapter are to comply with the requirements in Pt 4, Ch 1 of

Rules for the Classification of Steel Ships.

Fig 4.1.1 Spade rudder

102. Materials

1. Rudders stocks, coupling bolts, keys and cast parts of rudders are to be made of rolled steel, steel forging or carbon steel casting, conforming to the requirements in Rules for Classification of Steel Ships, Pt 2, Ch 1. For rudder stocks, coupling bolts and keys, the minimum yield stress is not to be less than 200 (N mm ). The requirements in this chapter are based on a material's yield stress

of 235 (N mm ). If material is used having a yield stress differing from 235 (N mm ) the

2. material

factor, is to be determined according to Table

411

excessive pressures at the edges of

bearings.

3. Welded members of rudders such as rudder plates, rudder frames, rudder main pieces, and edge bars are to be made of rolled steel for hull conforming to the requirements in Rules for

Classification of Steel Ships, Pt 2,

Ch 1. The required scantlings may be reduced when high ten-

sile steels are applied. When reducing

4.1.2.

the scantling, the material factor

is to be as

in Table

![]()

Table 4.1.1 Material Factor (for steel forging and car- Table 4.1.2 Material Factor

(for rol-

bon steel casting)

Material |

|

RA, RB, RD or RE | 1.0 |

RA32, RD 32 or RE 32 | 0.78 |

RA 36, RD 36 or RE 36 | 0.72 |

led steel)

(N mm ) |

|

> 235 |

|

≤ 235 |

|

NOTE: yield stress (N mm ) of material used, and not to exceed 0.7 or 450 (N mm ) whichever is small- er in value. = minimum tensile strength of material used (N mm ). | |

103. Sleeves and bushes

Bearings from the bottom of the rudder to well above the load line are to be provided with sleeves and bushes.