< Previous | Contents | Next >

Section 3 Hull Construction and Equipment

303. Passenger Ships

Passenger ships are to be accordance with following for the safety.

(1) For the inside of hull corresponding to the fire divisions(machinery spaces closed vehicle spaces and dangerous/inflammable liquid spaces) the "A-60"

of category A, en- class insulation ap-

proved of thickness/construction method or the equivalent is to be applied to bulkhead or deck of them. However, for the shell plating(top) insulation is to be extended to 300 mm under light water line and for others of shell plating(bottom) may be laminated with non-combustible resins (those of the burning resistance test in KS M3305) at least 3 times(thickness is to be not less

than 3 mm ).

(2) Inside of accommodation spaces, service spaces and control stations, which is not insulated with non-combustible ceilings or linings, is to be laminated with non-combustible resins at least 1 times.

(3) The Ceilings and linings used in accommodation spaces, service spaces and control stations are to be of non-combustible materials, and furniture and furnishings(including curtains, carpet, etc.)

are to be of restricted fire risk.(See the Ships Safety Law of Korea, Standard of Fire Protection, Article 23, ① and Appendix 1, Notes (6))

(4) In addition to the Ships Safety Law of Korea, Standard of Fire-Extinguishing Appliances Article 53(however, ② is to be applied to the ships having the main engine or auxiliary engines which

has sum of the output not less than 375 kW ), fire detection system is to be provided in not

manned machinery spaces of ship which has main engine controlled by the remote control system. Portable fire extinguisher of such machinery spaces is to be provided at the readily ac- cessible place.

304. Scantlings

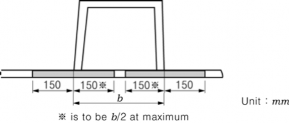

The effective breadth of FRP laminates of Hat-type construction is to be as shown by hatched areas in Fig 1.1.

![]()

2 Guidance relating to the Rules for the Classification of FRP Ships 2014

![]()

Fig 1.1 Effective Breath

305. Hat-type Construction

When the core for moulding of hat-type construction is reckoned in the section modulus, breadth of the core is to be calculated as NĂᾏÕĂᾚ Ń ∙ᾎ as shown in Fig 1.2. Ăᾏ and Ăᾚ are the modulus of bending elasticity of the core and FRP laminates respectively.

Pine and lauan 1.0

Plywood for structure -- 0.8

Other core material ----- To be determined by the test specified in Ch 3, 209. 2 of the Rules.

Fig 1.2 Inclusion of Core in Calculation

306. Sandwich Construction

When the core of sandwich construction is reckoned in bending strength, coefficient ǼĪ prescribed in Ch 6, 303. 1 of the Rules is to be determined by the following formula.

Ì

ÜĂ

ǼĪ Ņ

ᾏ

Ρ̓ÌŇÜ

Ì Ň ÜĂᾚ

N Ì Ñ ƒ ŃĮ

where

Ăᾏ :

Ăᾚ :

Modulus of bending elasticity of the core of sandwich construction (NÕmm Ī).

Modulus of bending elasticity of the outer laminates or inner laminates of FRP of sandwich construction (NÕmmĪ ).

Ü :

Ăᾏ as specified in 305. of the Guidance.

Ăᾚ

ƒ : as specified in Ch 6, 303. 1 of the Rules

307. Weight of Fibreglass Reinforcements and thickness of Laminates

To calculate the thickness of laminates for chopped mats or roving cloths, the following is to be described at the drawings submitted.

(1) Designed weight per unit area of chopped mats or roving cloths (gÕmĪ)

(2) Glass content of laminates(ratio in weight) (%)

(3) Specific gravity of cured resin.

(4) Specific gravity of chopped mats or roving cloths. ![]()

![]()