< Previous | Contents | Next >

Section 3 Windows

301. General

1. Windows in sides and ends of superstructures and deckhouses are to be of toughened safety glass and firmly mounted in stiff aluminium frames so that the glass is placed inside the outer point of side.

2. For craft with service restriction SA4, rubber frames may be accepted, provided the cross section is designed to increase the grip on the glass as the lateral pressure from outside is increased.

3. Materials other than toughened safety glass, except for front windows in wheelhouse, may be con- sidered by the Society. The thickness is then to be adapted to the strength of the material

![]()

concerned.

4. Window glass panes with heating wires are to be considered with regard to their reduced strength.

5. The cutouts for windows are to have well-rounded corners.

302. Thickness of glasses

1. The thickness of toughened safety glass panes is not to be less than that obtained from the ing formula :

follow-

mm

:

:

small dimension of window openings (mm ). 200, for toughened safety glass

190, for polycarbonate

lateral pressure defined in Pt 3, Ch 2, 304.

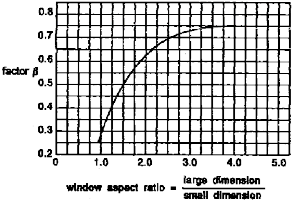

: factor, taken from Fig 4.4.1, dependent on the aspect ratio of the window.

Fig 4.4.1 Diagram for Factor

for Windows

2. The thickness of toughened safety glass panes may be reduced from that given by the formula in Pt 3, Ch 2, 304. when it is documented by a pressure test that the window fitted in the type of frame to be used is able to withstand a test pressure of 4 times the lateral design pressure accord- ing to previous Par 1 above without the window dropping out of the frame or leakage occurring. The thickness is not to be less than 5 mm .

3. Large glass doors or windows in the aft end of superstructures or deckhouses will be specially considered.

4. Windows of other materials than toughened safety glass ; i.e., polycarbonate, are to be tested in the type of frame to be used to a test pressure of 4 times the lateral design pressure according to Pt 3, Ch 2. It is to be documented that the window shows no sign of defects as specified in Par 2. Windows firmly fixed in the frames by bolting, gluing or other equivalent methods may be tested to a pressure of 2.5 times the lateral design pressure according to Pt 3, Ch 2. The thickness is not to be less than 5 mm .

303. Deadlights

1. The number of deadlights in relation to number of windows depending on the service restriction

![]()

notation, is to be as given in Table 4.4.3.

Table 4.4.3 Number of Deadlights

Location | Service area restriction notation | |||

SA0 | SA1 | SA2 | SA3 | |

Superstructure front 1 tier | 100 % | 100 % | 50 % | 25 % |

Superstructure side | 1 to each type of window 1 extra to dominating type of window | 0 | ||

Deckhouse front 2 tier and above | 1 to each type of window 1 | 0 | ||

Deckhouse side 2 tier and above | 1 to each type of window 1 | 0 | ||

NOTE: SA 4 may be specially considered. | ||||

2. Deadlights are to be interchangeable port and

3. Deadlights are to be stowed in such a way

starboard.

as to provide quick mounting. Deadlights for which

![]()

there is 100 % requirement, are to provide protection for intact windows. Other deadlights are to provide temporary replacement of damaged windows and may be mounted internally or externally over window openings. ![]()