< Previous | Contents | Next >

Section 8 Hopper Well Structure

801. General

1. The ends of hopper hold are to be provided with transverse bulkhead in whole breadth or web ring with sufficient strength.

2. It is recommended to provide the wear margin to each platings (wall of hopper hold, weir etc), where these margin might not interfere with dredging works.

802. Bulkhead plating and cellular keel plating

1. The thickness of bulkhead platings and cellular keel platings are not to be less than that obtained from the following formula.

ĖÅĬJĒY Ğ Ë Fmm F (However, Ź is not less that 10 mm ), ËĦËÄŊĦÈ FmmF YGẀĞYŊ ĞŊĦËẄË ĞŊĦŊĖÄỲ

Å : spacing of stiffeners (m )

d

h0

: distance between the lower edge of bulkhead or cellular keel plate and deck line (m )

: spacing from the top of weir to deck line (m )

b1

(when the top of weir is located below deck line,

: distance between longitudinal bulkheads (m )

h0 becomes minus(-))

ÄỲ : length of hopper hold (m )

2. The thickness of bulkhead platings of bucket well is to be determined with same thickness of shell platings.

3. For the structures and scantlings of coaming, buckling is to be specially considered.

803. Stiffeners

The scantlings of stiffeners of bulkhead and cellular keelson in hopper well are to be increased properly considering the specific gravity of mud.

Ch 1 0

![]()

804. Floors

1. The scantlings of open well with flap are to be determined by direct calculation method approved by this Society.

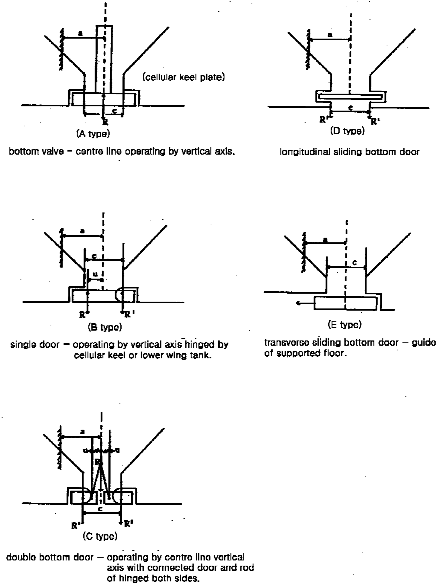

2. There are generally 5 type of flaps such as Fig 10.2 and the calculation sheet for the scantlings of flap is to be submitted and approved by this Society.

805. Gusset stays for trunk

The transverse rings are to be provided with gusset stays supported by trunk and both ends of gus- set stays are to be fitted rigidly.

806. Girder supporting hydraulic equipment

The girders supporting hydraulic equipment in hopper holds are to have sufficient strength to the force transmitted by hydraulic equipment. ![]()

Fig 10.2 Kind of flap