< Previous | Contents | Next >

Section 2 Hull Structures

201. Hull structure and Materials

1. Hull structure, materials, weldings and end connections are to be in accordance with the following depending upon the ship length:

(1) For ships which are 90 m or above, materials, hull equipment and end connections are to be according to Pt 3 and Pt 7 of Rules for the Classification of Steel Ships.

(2) For ships which are less than 90 m, materials, hull equipment, weldings and end connections

are to be according to Pt 10 of Rules for the Classification of Steel Ships.

2. The requirements in Pt 2, Ch 1 of Rules for the Classification of Steel Ships are to be ap- plied to materials used to hull structure unless specifically specified.

202. Strengthening for Heavy Cargoes

1. The requirements apply to Offshore Support Vessels intended to carry heavy deck cargo exceeding 25 kN/m2 or heavy liquid cargo with specific gravity greater than 1.025.

2. Heavy Cargoes

(1) The Special Feature Notation HDC(P, Locations) will be assigned additionally to vessels de- signed built with strengthened for carriage of heavy deck cargoes exceeding 25 kN/m2.

(2) The Special Feature Notation HLC(‚, Tanks) will be assigned additionally to vessels designed built with strengthened for carriage of heavy liquid cargoes with specific gravity exceeds 1.025.

3. Submission of Data

In general, the following plans and particulars are to be submitted.

(1) Heavy Deck Cargoes

(A) Structural details and arrangements of structures in way of cargo deck

(B) The design deck cargo loads in kN/m2 and locations

(C) Lashing arrangement of deck cargoes

(2) High Density Liquid Cargoes

(A) Tank arrangements and deep tank locations, together with their intended cargoes

(B) Specific gravity of highest density liquid cargoes for 100% filling of each tank

(C) Height of the air and overflow pipes for each tank

Guidance for Offshore Support Vessels 2015 9

Ch 3 Hull Structures and Equipment Ch 3

![]()

203. Side Fenders

1.For vessels subject to impact loads during routine operations the minimum side shell thickness is to be not less than 25% of the requirement of Rules for the Classification of Steel Ships, un- less effective permanent fenders are provided to protect the structure .

2.Continuous longitudinal fenders are generally to be fitted on the side shell at cargo deck. The fenders are to extend from the stern to a point not less than 0.02L forward of the section at which the full deck’s breadth starts decreasing; the area defined as an impact region. Additional fenders are to also be arranged diagonally at about 45° between the foregoing fenders, as necessary, to protect the side shell from the impact.

3.Fenders may be either permanent fenders constructed of steel or having exchangeable hard wood or rubber profile inserts. Carling plates or other effective means of stiffening are to be provided so that fender loads are effectively distributed to the hull structure. Steel fenders are to be efficiently welded to the shell plating with continuous fillet welds. Alternatively the fenders may be omitted also if the side plating is at least twice the thickness that is required by 1, for a height of at least 0.01L.

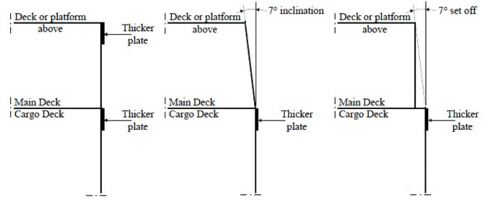

4. The upper plate may be omitted if the side shell is inclined 7° or set off 1:8 from the side’s ver- tical (Fig 3.1). The strength of the side frames, webs and stringers in the impact region is to be increased by the factor 1.25 over the standard requirements. All side structural members in the im- pact region shall have end connections with brackets. Scallop welds shall not be used in con- nections between side frames and shell plating.

Fig 3.1 Side Impact Plates