< Previous | Contents | Next >

Section 6 Watertight Integrity

601.

Watertight Bulkheads

1. General

(1) All units are to be provided with watertight bulkheads in accordance with the requirements in Pt 3, Ch 14 of Rules for the Classification of Steel Ships and Ch 14 of Rules for the Classification of Steel Barges. In the case of column-stabilized units, the scantlings of water-

![]()

tight flats and bulkheads are to quirements of damage stability.

(2) All surface type units are to be

be made of effective to that point necessary to meet the re-

provided with a collision bulkhead in accordance with the re-

quirements in Pt 3, Ch 14, 201. of Rules for the Classification of Steel Ships. However,

where openings, etc. are provided on collision bulkhead, the requirements for watertight doors in

Pt 3, Ch 14, Sec 4 and Pt 5, Ch 6, 107. of Rules for the Classification of Steel Ships

are to be satisfied.

2. Tank boundaries

(1) Tight divisions and boundary bulkheads of all tanks are to be constructed in accordance with the requirements in Pt 3, Ch 15 of Rules for the Classification of Steel Ships.

(2) Tanks for fresh water or fuel oil, or any other tanks which are not intended to be kept entirely

filled in service, are to have divisions or deep swashes as may be required to minimize the dy- namic stress on the structure.

(3) The arrangement of all tanks, together with their intended service and the height of the over-

flow pipes, is to be clearly indicated on the plans submitted for approval.

(4) Each tank is to be tested in accordance with Table 3.1.1 in

Classification of Steel Ships.

3. Boundary penetrations

Pt 3, Ch

1 of Rules for the

(1) The number of openings in watertight subdivisions should be

kept to a minimum compatible

with the design and safe operation of the unit. Where watertight boundaries are required for

damage stability, they are to be made watertight, including piping, ventilation, shafting, electrical penetrations, and so on. Piping systems and ventilation ducts within the extent of damage are to be provided with valves which are capable of being remotely operated from the weather deck, pump room, or other normally manned space, and are to be satisfactorily arranged to preclude the possibility of progressive flooding through the system to other spaces, in the event of damage. Valve position indicators are to be provided at the remotely operating positions.

(2) Notwithstanding the requirements in Par 1, non-watertight ventilation ducts are to be provided with watertight valves at the division boundaries and the valves are to be capable of being op-

erated from a remote location, with position indicators on the weather deck, or in a normally manned space. However, for self-elevating units, ventilating systems which are not used during

the transit condition may be secured by alternative methods approved by the Society. In this case, necessary ventilation for closed spaces is to be arranged at the discretion of the Society.

(3) Watertight doors should be designed to withstand water pressure to a head up to the bulkhead

deck or freeboard deck respectively. A prototype pressure test should be conducted for each type and size of door to be installed on the unit at a test pressure corresponding to at least the head required for the intended location. The prototype test should be carried out before the door is fitted. The installation method and procedure for fitting the door on board should correspond to that of the prototype test. When fitted on board, each door should be checked for proper seating between the bulkhead, the frame and the door. Large doors or hatches of a design and size that would make pressure testing impracticable may be exempted from the prototype pres- sure test, provided that it is demonstrated by calculations that the doors or hatches maintain wa- tertightness at the design pressure, with a proper margin of resistance. After installation, every such door, hatch or ramp should be tested by means of a hose test or equivalent.

602.

Closing Appliances

1. General

The construction and closing appliances of openings through which the in are to be in accordance with the requirements in Pt 4, Ch 3,

sea water is likely to flow

Sec 3 of Rules for the

Classification of Steel Ships and International Convention on Load Lines, except that those

which are provided in column-stabilized units, which are not located within areas of calculated im- mersion and for which special considerations are given, are to be at the discretion of the Society.

2. General requirements related to watertight integrity.

(1) External openings, such as air pipes (regardless of closing appliances), ventilators, ventilation in- takes and outlets, non-watertight hatches and weathertight doors, which are used during operation

of the unit while afloat, are not to submerge when the unit the righting moment and wind heeling moment curves in

is inclined any intact

to the first intercept of or damaged condition.

![]()

Openings, such as side scuttles of the non-opening type, manholes and small hatches, which are fitted with appliances to ensure watertight integrity, may be submerged.(Such openings are not allowed to be fitted in the column of stabilized units.) Such openings are not to be regarded as emergency exits. Where flooding of chain lockers or other buoyant volumes may occur, the openings to these spaces should be considered as downflooding points.

(2) External openings fitted with appliances to ensure watertight integrity, which are kept perma- nently closed while afloat, are to comply with the requirements of (5).

(3) Internal openings fitted with appliances to ensure watertight integrity are to comply with the fol- lowing:

(A) Doors and hatch covers which are used during the operation of the unit while afloat should

be remotely controlled from the central ballast control station and should also be operable locally from each side. Open/shut indicators should be provided at the control station. In ad- dition, remotely operated doors provided to ensure the watertight integrity of internal open- ings which are used while at sea are to be sliding watertight doors with audible alarm. The power, control and indicators are to be operable in the event of main power failure. Particular attention is to be paid to minimizing the effect of control system failure. Each power-operated sliding watertight door shall be provided with an individual hand-operated mechanism. It shall be possible to open and close the door by hand at the door itself from both sides.

(B) Doors or hatch covers in self-elevating units, or doors placed above the deepest load line draft in column-stabilized and surface units, which are normally closed while the unit is afloat may be of the quick acting type and should be provided with an alarm system (e.g., light signals) showing personnel both locally and at the central ballast control station wheth- er the doors or hatch covers in question are open or closed. A notice should be affixed to each such door or hatch cover stating that it is not to be left open while the unit is afloat.

(C) The closing appliances are to have strength, packing and means for securing which are suf- ficient to maintain watertightness under the design water pressure of the watertight boundary under consideration.

(4) Remotely operated doors should meet SOLAS regulation II-1/13-1.

(5) Internal openings fitted with appliances to ensure watertight integrity, which are to be kept per- manently closed while afloat, are to comply with the following:

(A) A signboard to the effect that the opening is always to be kept closed while afloat is to be

fitted on the closing appliance in question.

(B) Opening and closing of such closure devices should be noted in the unit’s logbook, or equivalent.

(C) Manholes fitted with bolted covers need not be dealt with as under (A).

(D) The closing appliances are to have strength, packing and means for securing which are suf- ficient to maintain watertightness under the design water pressure of the watertight boundary under consideration.

3. General requirements related to weathertight integrity.

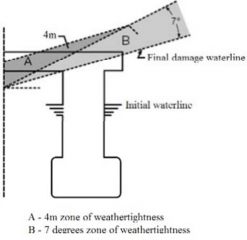

(1) Any opening, such as an air pipe, ventilator, ventilation intake or outlet, non-watertight side- scuttle, small hatch, door, etc., having its lower edge submerged below a waterline associated with the zones indicate in (A) or (B) below, is to be fitted with a weathertight closing appli- ance to ensure the weathertight integrity, when:

(A) a unit is inclined to the range between the first intercept of the right moment curve and the wind heeling moment curve and the angle necessary to comply with the requirements of

302. during the intact condition of the unit while afloat; and

(B) a column-stabilized unit is inclined to the range:

(a) necessary to comply with the requirements of 402. 1 (3) and with a zone measured 4.0 m perpendicularly above the final damaged waterline per 402. 1 (1) referred to Fig

4.4, and

(b) necessary to comply with the requirements of 402. 2 (3).

(2) External openings fitted with appliances to ensure weathertight integrity, which are kept perma- nently closed while afloat, are to comply with the requirements of 602. 2 (5) (A) and (B).

(3) External openings fitted with appliances to ensure weathertight integrity, which are secured while

afloat are to comply with the requirements of 602. 2 (3) (A) and (B).

![]()

Fig 4.4 Minimum weathertight integrity requirements for column-stabilized units