< Previous | Contents | Next >

SURVEY PLANNING QUESTIONNAIRE

The following information will enable the Owner in co-operation with the Society to develop a survey programme complying with the requirements of the Rules. It is essential that the Owner provides, when

completing the present questionnaire, up-to-date information. provide all information and material required by the Rules.

The present questionnaire, when completed, is to

Basic information and particulars

Name of ship : | |

Class No. : | IMO No. : |

Class Notation : | |

Flag State : | |

Port of registry : | |

Gross tonnage : | |

Deadweight(metric tones) : | |

Length between perpendiculars(m) : | |

Shipbuilder : | |

Hull number : | |

Date of delivery of the ship : | |

Date of build / major conversion : | / |

Owner : | |

Thickness measurement company : | |

Owner's representative :

Signature

Name

( Place / Date )

![]()

Guidance Relating to the Rules for the Classification of Steel Ships 2015 117

Pt 1 Classification and Surveys

Annex 1-3 Example of the Survey Programme and the Survey Planning Questionnaire Pt 1, Annex 1-3

![]()

SURVEY PLANNING QUESTIONNAIRE

1. Information on access provisions for Close-up Surveys and thickness measurement

The Owner is to indicate, in the table below, the means of access to the structures subject to Close-up Survey and thickness measurement. A Close-up Survey is an examination where the details of structural components are within the close visual inspection range of the attending Surveyor, i.e. normally within reach of hand.

Hold/Tank/ Space | Structure* | C(Cargo)/ B(Ballast) | Access provisions | |||||

Permanent Means of Access | Temporary staging | Rafts/Boats | Ladders | Direct access | Other means (please specify) | |||

* Each structural components which have different type of access provisions are to be specified.

(e.g. Fore peak/Aft peak/Under deck/Side shell/Bottom transverse/Longitudinal/Transverse/Hatch side coamings/Topside slopping plate/Upper stool plating/Cross deck/Side shell, frames & brackets/Transverse bulkhead/Hopper slopping plating/Lower stool/Tank top/Double bottom structure/Upper stool internal structure/Lower stool internal structure, etc.)

![]()

History of bulk cargoes of a corrosive nature(e.g. high sulphur content) /

![]()

History of cargo with H2S content or heated cargo for the last 3 years together with indication as to whether cargo was heated and, where available, Marine Safety Data Sheets(MSDS)*

![]()

![]()

![]()

![]()

![]()

![]()

* Refer to resolution MSC.150(70) on Recommendation for material safety data sheets for MARPOL Annex I cargoes and marine fuel oils.

118 Guidance Relating to the Rules for the Classification of Steel Ships 2015

![]()

Pt 1 Classification and Surveys

Annex 1-3 Example of the Survey Programme and the Survey Planning Questionnaire Pt 1, Annex 1-3

![]()

SURVEY PLANNING QUESTIONNAIRE

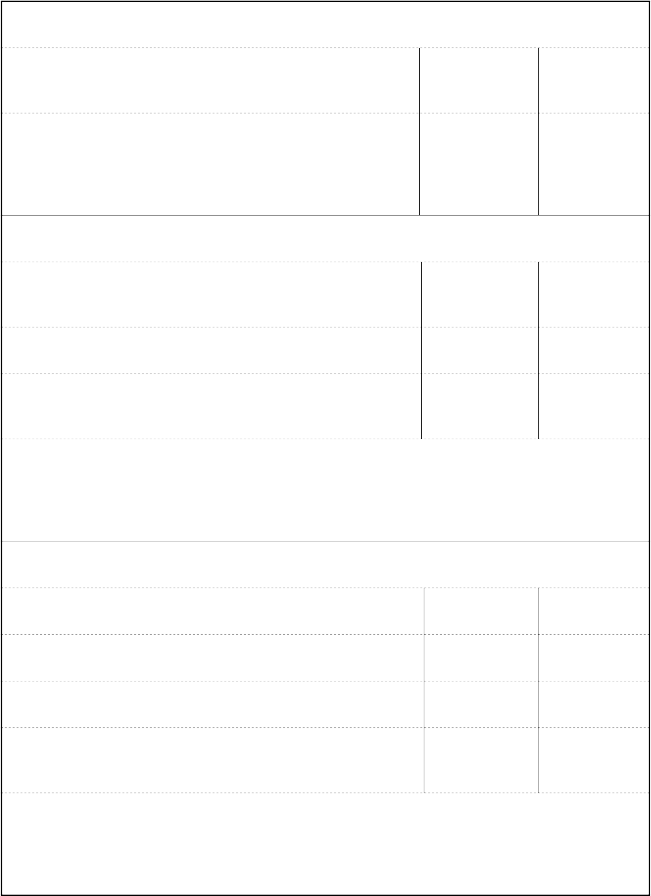

2. Owner's inspections

Using a format similar to that of the table below (which is given as an example), the Owner is to provide details of the results of their inspections for the last 3 years on all cargo holds/tanks, ballast tanks and void spaces within the cargo (length) area, including peak tanks.

![]()

Hold/Tank/Space Use

Corrosion

![]()

prevention system (1)

Coating extent (2)

Coating condition (3)

Structural deterioration (4)

Hold/tank/space history

(5)

![]()

![]()

![]()

(1) HC=hard coating,

(2) U=upper part,

(3) G=good,

SC=soft coating, M=middle part, F=fair,

SH=semi-hard coating, L=lower part,

P=poor,

NP=no prevention C=complete

RC=recoated(during the last 3 years)

(4) N=no findings recorded,

Y=findings recorded, description of findings is to be attached to the questionnaire

(5) DR=damage & repair, L=leakages,

![]()

CV=conversion(description is to be attached to the questionnaire)

Owner's representative :

Signature

Name

( Place / Date )

Guidance Relating to the Rules for the Classification of Steel Ships 2015 119

Pt 1 Classification and Surveys

Annex 1-3 Example of the Survey Programme and the Survey Planning Questionnaire Pt 1, Annex 1-3

![]()

SURVEY PLANNING QUESTIONNAIRE

3. Reports of Port State Control inspections

![]()

![]()

List the reports of Port State Control inspections containing hull structural related deficiencies and relevant information on rectification of the deficiencies:

![]()

![]()

![]()

![]()

![]()

4. Safety Management System

![]()

List non-conformities related to hull maintenance, including the associated corrective actions:

![]()

![]()

![]()

![]()

![]()

![]()

5. Name and address of the approved thickness measurement company

![]()

Name Address Approved by

![]()

![]()

![]()

![]()

![]()

120 Guidance Relating to the Rules for the Classification of Steel Ships 2015

Pt 1 Classification and Surveys

Annex 1-4 Owners Inspection Report Pt 1, Annex 1-4

![]()

Annex 1-4 Owners Inspection Report

The Owner of ships subject to the enhanced survey programme such as bulk carriers, oil tankers and chemical tank-

ers, etc. is to complete the Owner Inspection Report and retain it inside the ship, according

103. of the Rules. An example of the Owner Inspection Report is shown in Table 1.

to requirement Ch 3,

Elements | Cracks | Buckling | Corrosion | Coating Cond. | Pitting | Rep., Mod | Other |

Deck | |||||||

Bottom | |||||||

Side | |||||||

Longi. BHD | |||||||

Trans BHD |

Table 1 Example of Owner Inspection Report

Owners Inspection Report(Structural Condition) |

· Deck : ․ Side : · Bottom : ․ Longi. BHD : · Trans. BHD :

· Date : · Result in General :

|

Date of Inspection : Inspected by : Signature : |

![]()

![]()

Guidance Relating to the Rules for the Classification of Steel Ships 2015 121

![]()

Pt 1 Classification and Surveys

Annex 1-5 Thickness Measurement Method for Hull Structural Member Pt 1, Annex 1-5

![]()

Annex 1-5 Thickness Measurement Method for Hull Structural Members

1. General

(1) Purpose of thickness measurement

(A) Corrosion seems to be one of the common denominators in many cases of serious hull cas- ualties resulting in losses of vessels, cargoes and human lives. The purpose of thickness measurement described in the Rules is to prevent vessels from hull casualties. Information provided in the report of hull thickness measurements for a vessel put in service indicates that the vessel is maintaining sufficient local and global strength, if necessary renewal/repair works can be made accordingly. Therefore, thickness measurement reports giving information for the assessment of hull strength(including watertight integrity) as well as for the main- tenance of the hull is to be carefully considered.

(B) Where the ship has been constructed with FRP, aluminum alloy or other anti-corrosion ma- terials, the thickness measurements may be dispensed with.

(2) Extent of thickness measurement

The standard extent of thickness measurements complying with the "Rules for Classification of Steel Ships" is given in Table 4 to Table 13. However, the extent of thickness measurements may be specially considered by the Society, considering the coating and corrosion condition.

(3) Thickness measurement report

(A) The thickness measurement report submitted to the Society shall include the general partic- ulars as shown in Table 19, measuring position, diagram with details of the position to be

measured, original thickness, maximum allowable diminution and present thickness(gauged) and diminution, etc. Reporting form shown in Table 20(or equivalent form) is to be used

for recording measuring position, original thickness, maximum allowable diminution, present

thickness(gauged) and diminution, etc.

(B) The thickness measurement report is to be verified and countersigned by the attending Surveyor, and the record is to be kept in the Society and on board the ship.

2. Wear Limit

(1) General

(A) This annex provides standard of wear limit for decision of repair of main hull structural members. Wear limit or allowable wear quantity means allowable wear limit.

(B) When worn down thickness of hull structural members exceed the wear limit, inspections

are to be carried out in detail and corresponding hull structural members are to be renewed by the date recommended by the Surveyor.

(C) Wear limit provided by this annex is based on the requirements and scantlings during

construction. Therefore, the wear limit for the structural members which have scantlings larger than the required ones and margin in strength may be considered appropriately.

(D) Wear limit on hull structural members not provided by this annex follows what is deemed appropriate by the Surveyor.

(2) Wear limit on hull structural members

(A) Wear limits on structural members are provided in Table 1. However, for vessels built un-

der IACS Common Structural Rules(Pt 11, Pt 12 or Pt 13), Pt 1, Ch 3, 105. 2 of the Rules is to be applied.

(B) Value of wear limit indicates the limit on equally distributed wearing.

(C) When partial corrosion occurs in stress concentrated part, partial replacement or reinforce- ment shall be carried out without reference to Table 1.

122 Guidance Relating to the Rules for the Classification of Steel Ships 2015

![]()

Pt 1 Classification and Surveys

Annex 1-5 Thickness Measurement Method for Hull Structural Member Pt 1, Annex 1-5

![]()

![]()

![]()

![]()

Table 1 Wear limit on members

Local Wear Limit | Name of member | Wear limit | ||

Class 1) | Class 1) | Class 1) | ||

Strength deck plating, sheer strake and longitudinals to these members, shell plating, bottom shell plating, bulkhead plating of deep tank4), topside sloping plating, hopper side sloping plating, inner bottom plating | 20 % of original thickness | (20 % of original thickness) + 1 mm | 1 mm | |

Floor & girder of double bottom, web and face of primary supporting member | 20 % of original thickness | 25 % of original thickness | ||

Effective deck5) plating, superstructure deck plating, deck plating inside the line of cargo hatch openings, watertight bulkhead plating other than bulkhead plating of deep tank, hatch cover(including stiffeners), hatch coaming(including stiffeners), web, face and brackets of secondary stiffener3) | 25 % of original thickness | 30 % of original thickness | ||

Web, face and brackets of frames in cargo hold/tank | 20 % of original thickness or 1.5 mm , whichever greater | 25 % of original thickness or 2.5 mm , whichever greater | ||

Partial corrosion (e.g pitting) | 30 % of original thickness | 35 % of original thickness | ||

(NOTES) 1) For ships classed through the Classification Survey during Construction : the Class I, II and III are as follow. (a) Class I : It is applied to ships having one or two of the following characteristics. (i) Ships, with of length of 90 m and above, which are classed with Classification Survey during Construction in accordance with the Rules after 1st July 1998. (ii) Ships carry for liquid cargo, which are classed with Classification Survey during Construction in accordance with the Rules after 1st July 1998. (b) Class II : Ships, other than in Class I and III. (c) Class III : Ships constructed with steel, which is applied to the Rules for the Classification of High Speed and Light Crafts and the Guidance Relating to the Rules for the Classification of High Speed and Light Crafts. 2) For ships classed through the Classification Survey after Construction, the separate requirements specified by the Society are to be applied. 3) Secondary stiffener refers to the member which is supported by the primary supporting member and does not support another reinforcement member. 4) Definition of deep tank is specified in Pt 3, Ch 15, 101. of the Rules. 5) Definition of effective deck is specified in Pt 3, Ch 5, 103. of the Rules. | ||||

Wear relati ng to the Shearing Strength | The shearing strength evaluation is to be carried out in any of the following cases when the thickness measurement for the longitudinal strength evaluation is carried out in accordance with the separate re- quirements specified by the Society. 1) For oil tankers(including chemical tankers), the average corrosion of any stake in side shell or lon- gitudinal bulkhead exceeds the followings, Class I : 2.0 mm Class II : 3.0 mm 2) For liquefied gas carriers, the average corrosion of any stake in side shell bulkhead exceeds the followings, or Class I : 1.5 mm Class II : 2.5 mm 3) For bulk carriers(including ore carriers) intended for alternate loading, the average corrosion of any stake in side shell or longitudinal bulkhead exceeds the followings Class I : 1.5 mm Class II : 2.5 mm | |||

Guidance Relating to the Rules for the Classification of Steel Ships 2015 123

![]()

Pt 1 Classification and Surveys

Annex 1-5 Thickness Measurement Method for Hull Structural Member Pt 1, Annex 1-5

![]()

(3) Wear limit of hold hatch cover of bulk carriers which are contracted for construction after 1st July 1998 and before 1st January 2004 and designed by the Rules Pt 7, Ch 3, Sec 9 is to be determined in accordance with the following requirements.

(A) Single skin hatch covers and the pontoon hatch covers

![]()

(a) Steel renewal is required where the gauged thickness is worn more than 1.5 mm (less than mm ). The net ![]() is the thickness obtained by subtracting the corrosion addition from the required thickness.

is the thickness obtained by subtracting the corrosion addition from the required thickness.

(b) Where the gauged thickness is worn within the range 1.0 mm and 1.5 mm

![]()

![]()

( mm and mm ), coating applied in accordance with coating

manufactur- er's requirements or annual gauging may be adopted as an alterative to steel renewal.

(B) Internal structural members of pontoon hatch covers

previous (a) or when it is deemed necessary, at the discretion of the Society, on the basis

of the plating corrosion or deformation condition. In these cases,

![]()

ternal structures is required where the gauged thickness is worn than

steel renewal for the in-

more than 1.5 mm (less

(4) Wear limit of hold hatch cover and hatch coatings of all bulk carriers, ore carriers and combi-

nation carriers by the Rules requirements.

which are contracted for construction on or after 1st January 2004 and designed

Pt 7, Ch 3, Sec 9 is to be determined in accordance with the following

(A) Single skin hatch covers and double skin hatch covers

![]()

(a) Steel renewal is required where the gauged thickness is worn more than 1.5 mm (less than mm ).

(b) Where the gauged thickness is worn within the range 1.0 mm and 1.5 mm

![]()

![]()

( mm and mm ), coating applied in accordance with coating

manufactur- er's requirements or annual gauging may be adopted as an alterative to steel renewal. Coating is to be maintained in GOOD condition, as defined in Pt 1, Ch 2, 101. 16 of the Rules

(B) Internal structural members of double skin hatch covers

Thickness gauging is required when plating renewal is to be carried out in accordance with

previous (a) or when it is deemed necessary, at the discretion of the Society, on the basis

of the plating corrosion or deformation condition. In these cases,

ternal structures is required where the gauged thickness is worn than ![]()

(C) Hatch coamings

steel renewal for the in- more than 1.5 mm (less

(a) Steel renewal is required where the gauged thickness is worn more than 1.0 mm (less

than ![]()

(b) Where the gauged thickness is worn within the range 0.5 mm and 1.0 mm

![]()

![]()

( mm and mm ), coating applied in accordance with coating

er's requirements or annual gauging may be adopted as an alterative to steel renewal.

Coating is to be maintained in GOOD condition, as defined in Pt 1, Ch 2, 101. 16 of

the Rules

![]()

(5) The renewal thickness( ) of steel hatch covers and coamings in position I and II on

ex- posed decks, subjected to Pt 4, Ch 2, of ships other than bulk carriers which are keel laid on or after 1st January 2005 are to be in accordance with as followings. (Refer to Pt 4, Ch 2,

![]()

(mm)

![]()

Where,

: as built thickness

![]() : corrosion addition according to Pt 4, Ch 2, 105. Table 4.2.1 of the Rules

: corrosion addition according to Pt 4, Ch 2, 105. Table 4.2.1 of the Rules

Where the corrosion addition ![]() is 1.0 mm , the renewal thickness may be given by the following formula

is 1.0 mm , the renewal thickness may be given by the following formula

![]()

(mm)

124 Guidance Relating to the Rules for the Classification of Steel Ships 2015

Pt 1 Classification and Surveys

Annex 1-5 Thickness Measurement Method for Hull Structural Member Pt 1, Annex 1-5

![]()

(6) Wear limit of corrugated transverse watertight bulkheads for bulk carriers, which are contracted for construction after 1st July 1998 and designed by the Rules Pt 7, Ch 3, 1201. is to be de- termined in accordance with the following requirements.

(A) Steel renewal is required where the gauged thickness is worn more than 3.0 mm (less than

![]()

mm ).

(B) Where the gauged thickness is worn within the range 2.5 mm and 3.0 mm (![]()

mm

![]()

and mm ), coating applied in accordance with coating manufacturer's requirements or

annual gauging may be adopted as an alterative to steel renewal.

(7) Corrosion addition and steel renewal of vertically corrugated transverse watertight bulkheads be-

tween cargo holds No. 1 and 2 for bulk carriers, which are applied to Pt 7, Annex 7-5, 1 (1)

(8) The wastage allowances of supporting hull structures associated with ject to Pt 4, Ch 10 of the Rules, of ships which are keel laid on

towing and mooring, sub- or after 1st January 2007

are not to exceed the corrosion addition as specified in Pt 4, Ch 10, 201. 6 and 202.

the Rules.

6 of

3. Methods of Thickness Measurement

An essential part of most surveys is the determination of the residual thickness of the structure in critical areas. Ultrasonic thickness gauging by pulse echo method is used almost exclusively for this purpose. However, measuring by drilled holes may also be acceptable. As a method of thick- ness measurement, where ultrasonic thickness gauging methods are used, attention is to be paid to the following:

(1) Surface condition

Surfaces upon which the probe makes contact are to be sufficiently free from scale, loose paint, corroded surfaces or other foreign matters to the extent that their presence does not result in in- accurate readings when acoustic couplants such as glycerine or glycerine-water solutions are

used during inspection. In special cases, readings through paint film by a special instrument may be accepted.

(2) Couplants

It is essential that good acoustic contact is achieved between the probe and the surface of the plate being measured. Therefore, acoustic couplants(e.g., coupling fluid; 75 % glycerine-water sol- utions or glycerine) between the probe and surface of material are usually used for better

achievements. Where the direction of contact surfaces is vertical or overhead, a paste or liquid with suitable viscosity may be used to prevent acoustic couplants from dropping.

(3) Calibrations

An instrument is to be calibrated with a reference calibration standard each time it is used, and it is to be recalibrated whenever equipment calibration is suspected of being in error.

4. Location of Thickness Measurement

(1) Thickness measurements for suspect area

At each Special Survey, the thickness gaugings may be required as in suspect areas(i.e., locations showing substantial corrosion and/or

to be prone to rapid wastage). Details are given in Table 2.

(2) Location and number of thickness measuring points

The standard location and number of thickness measuring points

a result of Close-up Survey considered by the Surveyor

and patterns are shown in

Table 3. These figures show typical arrangements of ships such as bulk carriers and oil tank-

ers, etc. and these may be used as guidance for different type of ships other than those illustrated. The location and number of thickness measuring points for other hull structural mem- bers which are not specified in this Annex are to be in accordance with what considered appro-

priate by the Surveyor taking into account of the ship's age and hull structure, etc.

(3) Thickness Measurement at Special Survey

The standard extent of thickness measurements at each Special Survey are given in Table 4 to

Table 13.

Guidance Relating to the Rules for the Classification of Steel Ships 2015 125

Pt 1 Classification and Surveys

Annex 1-5 Thickness Measurement Method for Hull Structural Member Pt 1, Annex 1-5

![]()

5. Additional Thickness Measurement

The extent of additional thickness measurement at those areas of substantial corrosion of ships sub- ject to the enhanced survey programme such as bulk carriers, oil tankers and chemical tankers, etc. is shown in Table 14 to Table 18.

6. Sampling method of thickness measurements for longitudinal strength evaluation and re- pair methods for oil tankers or double hull oil tankers subject to the enhanced survey programme

(1) Extent of longitudinal strength evaluation

Longitudinal strength should be evaluated within 0.4 ![]() amidships for the extent of the hull gird- er length that contains tanks therein and within 0.5

amidships for the extent of the hull gird- er length that contains tanks therein and within 0.5 ![]() amidships for adjacent tanks which may

amidships for adjacent tanks which may

![]()

(2) Sampling method of thickness measurement

(A) Pursuant to the requirements of Ch 3, 304. 4 or 504. 4 of the Rules as applicable, trans-

verse sections should be chosen such that thickness measurements can be taken for as many different tanks in corrosive environments as possible, e.g. ballast tanks sharing a com- mon plane boundary with cargo tanks fitted with heating coils, other ballast tanks, cargo

tanks permitted to be filled with sea water and other cargo tanks. Ballast tanks sharing a common plane boundary with cargo tanks fitted with heating coils and cargo tanks permit- ted to be filled with sea water should be selected where present.

(B)

(C)

(D)

(E)

(F)

The minimum number of transverse sections to be sampled should be in accordance with

Ch 3, Table 1.3.5 or Table 1.3.11 of the Rules as applicable. The transverse sections

should be located where the largest thickness reductions are suspected to occur or are re- vealed from deck and bottom plating measurements prescribed in (C) and should be clear

of areas which have been locally renewed or reinforced.

At least two points should be measured on each deck plate and/or bottom shell plate re- quired to be measured within the cargo area in accordance with the requirements of Ch 3,

Table 1.3.5 or Table 1.3.11 of the Rules as applicable.

Within 0.1 ![]() (where

(where ![]() is the ship's moulded depth) of the deck and bottom at each trans- verse section to be measured in accordance with the requirements of Ch 3, Table

is the ship's moulded depth) of the deck and bottom at each trans- verse section to be measured in accordance with the requirements of Ch 3, Table

1.3.5 or

Table 1.3.11 of the Rules as applicable, every longitudinal and girder should be measured on the web and face plate, and every plate should be measured at one point between

longitudinals.

For longitudinal members other than those specified in (D) above to be measured at each transverse section in accordance with the requirements of Ch 3, Table 1.3.5 or Table

1.3.11 of the Rules as applicable, every longitudinal and girder should be measured on the

web and face plate, and every plate should be measured at least in one point per strake. The thickness of each compartment should be determined by averaging all of the measure-

(3) Additional measurements where the longitudinal strength is deficient.

(A) Where one or more of the transverse sections are found to be deficient in respect of the

longitudinal strength requirements, the number of transverse sections for thickness measure- ment should be increased such that each tank within the 0.5 ![]() amidships region has been sampled. Tank spaces that are partially within, but extend beyond, 0.5

amidships region has been sampled. Tank spaces that are partially within, but extend beyond, 0.5 ![]() region,

region,

should be sampled.

(B)

Additional thickness measurements should also be performed on one transverse section for-

ward and one aft of bordering the repaired

each repaired area to the extent necessary to ensure that the areas section also comply with the requirements of the Rules.

126 Guidance Relating to the Rules for the Classification of Steel Ships 2015

Pt 1 Classification and Surveys

Annex 1-5 Thickness Measurement Method for Hull Structural Member Pt 1, Annex 1-5

![]()

(4) Effective repair methods

(A) The extent of renewal or reinforcement carried out to comply with the Rules should be in accordance with (B) below.

(B)

The minimum continuous length of a renewed or reinforced structural member should be not less than twice the spacing of the primary members in way. In addition, the thickness

diminution in way of the butt joint of each joining member forward and aft of the re-

placed member(plates, stiffeners, girder webs and flanges, etc.) should not be within the

(C)

substantial corrosion range(75% of the allowable webs and flanges,

within the substantial corrosion range(75% of the allowable diminution particular member). Where differences in thickness at the butt joint lower thickness, a transition taper should be provided.

Alternative repair methods involving the fitting of straps or structural

etc.) should not be

associated with each exceed 15% of the

member modification

should be subject to special consideration. In considering the fitting of straps, it should be limited to the following conditions:

(a) to restore and/or increase longitudinal strength;

(b) the thickness diminution of the deck or bottom plating to be reinforced should not be within the substantial corrosion range(75% of the allowable diminution associated with the deck plating):

(c)

(d)

(e)

the alignment and arrangement, including the termination of the straps, is in accordance with the separate requirements specified by the Society;

the straps are continuous over the entire 0.5 ![]() amidships length; and

amidships length; and

continuous fillet welding and full penetration welds are used at butt welding and, de- pending on the width of the strap, slot welds. The welding procedures applied should be

acceptable to the Society.

(D) The existing structure adjacent to replacement areas and in conjunction with the fitted

straps, etc. should buckling resistance

envelope plating.

be capable of withstanding the applied loads, taking into account the

and the condition of welds between the longitudinal members and hull

Guidance Relating to the Rules for the Classification of Steel Ships 2015 127

Pt 1 Classification and Surveys

Annex 1-5 Thickness Measurement Method for Hull Structural Member Pt 1, Annex 1-5

![]()

Table 2 Suspect areas on which attention is to be paid

Location | Measuring Points | |

Deck and upper structures | Special attention is to be given on fore parts (forward of 0.5 | |

F'cle, poop and deckhouse | Break bulkheads of superstructures, Lower parts of deckhouse walls, Pipe penetration areas, Areas with drain plugs, Deck platings of superstructures, Deck platings in way of bilge- ways, deck scuppers, deck machinery(winches, windlasses etc.), fair-leaders and bollards etc. | |

Deck platings inside line of hatch openings and inside superstructures and deckhouses | Deck platings inside line of openings between cargo hatch- ways, and of deck platings inside superstructures and deckhouses. | |

Hatch coamings and coaming stays | Lower parts attached to upper deck, Parts around steam pipes. | |

Bulwark platings and bulwark stays | Lower parts attached to upper deck, End parts connected to superstructures and deckhouses, Platings around freeing ports. | |

Winch foundation | Special attention is to be given to steam winch foundations | |

Steel hatch covers | Steel pontoon covers (including cleats, etc.) | |

Shells | Wind and water strakes | Special attention is to be given to fore and after part outside of 0.5 |

Shell platings connected to end brackets | After removal of limber boards and cement chocks, Close-up Survey is required. | |

Shells attached to hold frames | Special attention is to be given to groovings on shells. | |

Shells around chain lockers | - | |

Hard spotted shells | Special attention is to be given to shells (parts or positions) in ballast tanks | |

Internal members | Special attention is to be given to areas with high humidity, standing bilges and poorly ventilated spaces in addition to the following : | |

Joint parts between hold frames and frame brackets | After removal of limber board, those parts are to be exam- ined (problem areas in aged ships) | |

Intersections between transverse W/T Bulkhead and inner bottom | After removal of bottom ceilings, those parts are to be examined. | |

Tank top platings of double bottom tanks and of deep tanks used as ballast tanks | - | |

Fillet weld parts between hold frames and side shells | Special attention is to be paid to hold frames in intermittent welds. | |

Bilge wells | Special attention si to be given to bilge wells in E/R and bilge wells with piping arrangements. | |

Inner bottom platings under pillars | - | |

Internal members around sea water pumps in E/R | - | |

Sea chest boundaries in E/R | - | |

Joint parts between shaft tunnel and inner bottom | Close-up Survey is required for aged ships | |

Intersections between tweendeck frames or tweendeck bulkheads and lower deck | - | |

Lower parts of collision BHD and bottom of chain lockers | - | |

Intersections between panting/side stringers and frames, and end parts, slot areas in way of panting/side stringers | - | |

128 Guidance Relating to the Rules for the Classification of Steel Ships 2015

![]()

Pt 1 Classification and Surveys

Annex 1-5 Thickness Measurement Method for Hull Structural Member Pt 1, Annex 1-5

![]()

Table 2 Suspect areas on which attention is to be paid (continued)

Location | Measuring Points | |

Inside of tanks | Special attention is to be paid to the combined tanks (ballast and fuel oil), prone to rapid wastage, in addition to the following: | |

All of ballast tanks in front of E/R boundaries | Close-up Survey is required for tank top, bottom and boundary plat- ings of the tanks not forming their boundaries by full envelope (both shells and decks). And special attention is to be paid to connections between frames and brackets, and on docking brackets, lightening holes | |

Double bottom ballast tanks, side ballast tanks, and shaft tunnels | Special attention is to be paid to inner bottom platings meeting bulk- heads, edge platings reaching to tank side brackets, and on lightening holes/slots in way of girders and on bottom shells around striking pads below sounding pipes. | |

Bulkheads facing a heated zone | Special attention is to be paid to bulkheads facing E/R space, or fuel oil tanks being heated. | |

Bottom platings below sound- ing pipes | Special attention is to be paid to bilge tanks in E/R | |

Chain lockers in fore peak tanks | Special attention is to be paid to bottom platings and side boundaries of chain lockers. | |

Guidance Relating to the Rules for the Classification of Steel Ships 2015 129

![]()

Pt 1 Classification and Surveys

Annex 1-5 Thickness Measurement Method for Hull Structural Member Pt 1, Annex 1-5

![]()

Table 3-1 Location and number of thickness measuring points - Non-CSR Ships

Table 3-1 is to be applied to vessels not built under IACS Common Structural Rules(Pt 11, Pt

(i.e. Non-CSR Ships)

12 or Pt 13)

Items | Location and number of thickness measuring points |

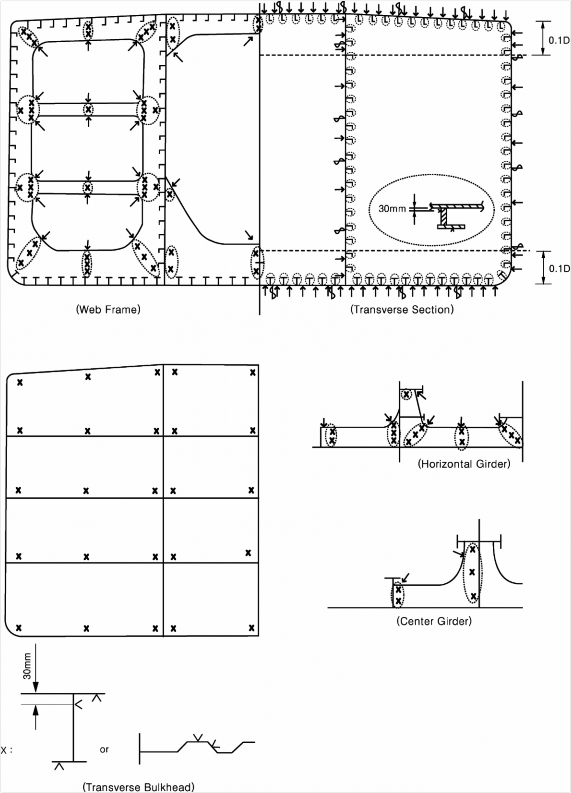

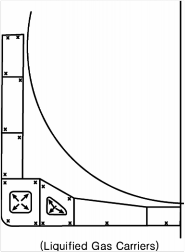

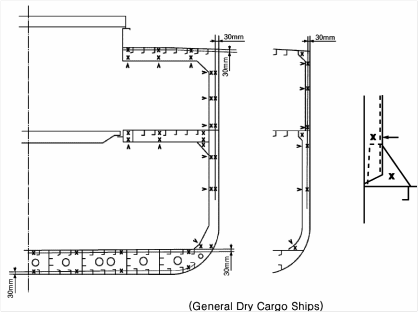

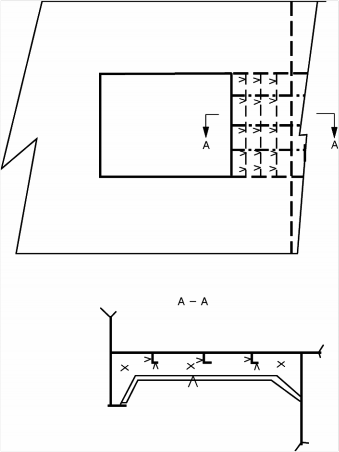

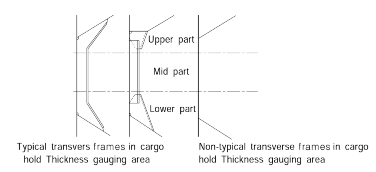

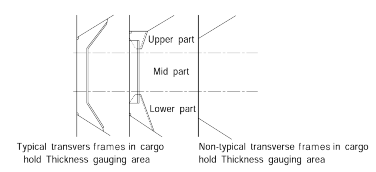

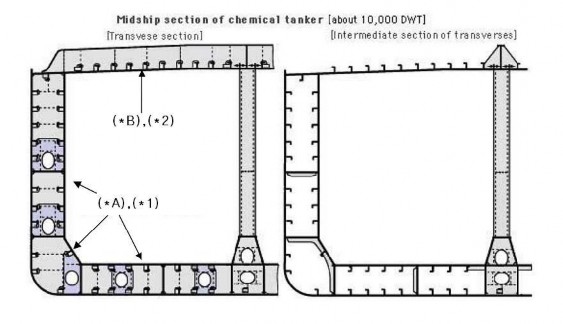

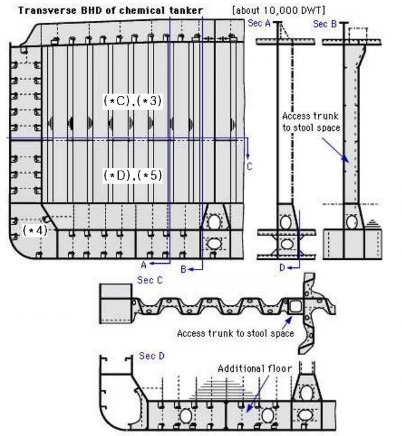

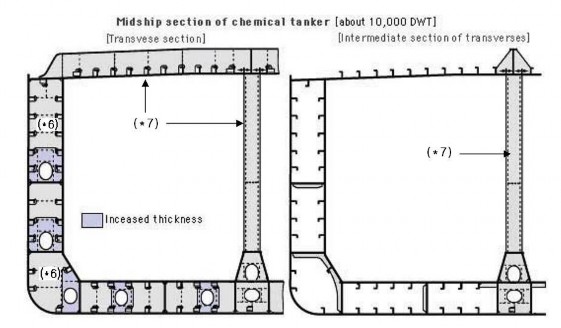

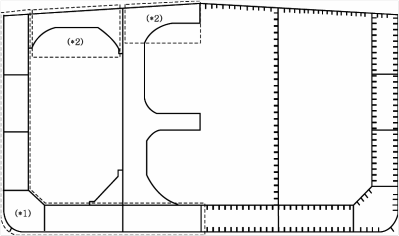

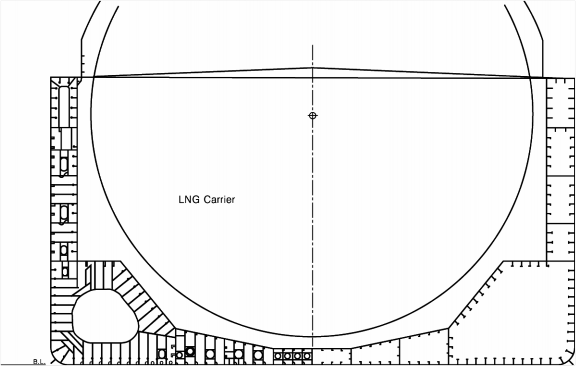

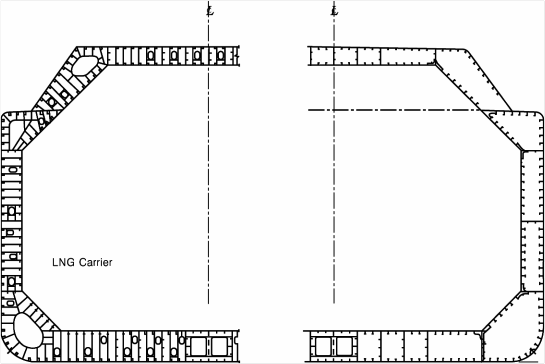

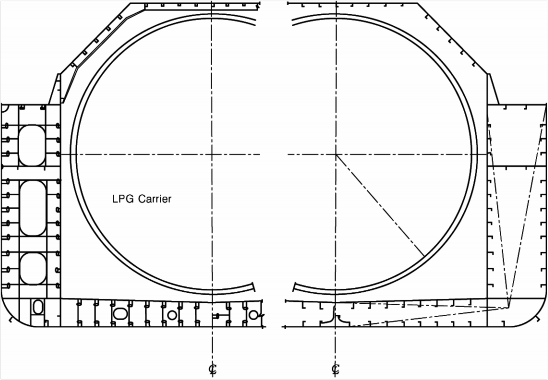

Transverse Section | 1. For oil tankers, chemical tankers or double hull oil tankers subject to the enhanced survey programme (See Fig 1 and Fig 2) (1) At each transverse section, every plate within 0.1D(where D is the ship's mould- ed depth) of the deck and bottom is to be measured at one point between lon- gitudinals, and all the other plate is to be measured at least one point per strake. (2) Where the thickness measurements for a transverse section are to include all longitudinal members, every longitudinal is to be measured at one point on the web and face plate. 2. For single skin bulk carriers, double skin bulk carriers or general dry cargo ships (See Fig 3 and Fig 4) (1) At each transverse section, every plate of the deck and inner bottom is to be measured at one point between longitudinals, and all the other plate is to be measured at least one point per strake. (2) Where the thickness measurements for a transverse section are to include all longitudinal members, every longitudinal is to be measured at one point on the web and face plate. 3. For general ships other than 1 and 2 above (See Fig 5) (1) At each transverse section, every plate is to be measured at least two points per strake. (2) Where the thickness measurements for a transverse section are to include all longitudinal members, every longitudinal is to be measured at one point on the web and face plate. 4. For transversely framed vessels, a transverse section includes adjacent frames and their end connections in way of transverse sections. (For oil tankers, chemical tankers or double hull oil tankers subject to the en- hanced survey programme see Fig 1 and Fig 2, for single skin or double skin bulk carriers see Fig 6 and Fig 8, for other ships see Fig 7) |

Transverse Section of deck, side shell and bottom plating | At least two points on each plate(either at each 1/4 extremity of plate or at repre- sentative areas of average corrosion) are to be measured in the transverse section concerned. |

Selected plates: Selected plates on deck(including deck inside line of hatch openings), tank top, bottom, inner bottom plates, etc. and wind-and-water strakes | At least two points are to be measured at representative areas of average corrosion. Where the length of the plate exceeds 6 m , two points per 6 m are to be gauged additionally. Where plates cross ballast/cargo tank boundaries separate measurements for the area of plating in way of each type of tank are to be taken. In case of side shell plating, one or two wind and water strakes are to be gauged according to No. of Special Survey. The gauging location of each plate may be selected by the attending Surveyor in consideration of the corrosion pattern. |

All plates: All deck(including deck inside line of hatch openings), tank top, bottom, inner bottom plates, etc. and wind-and-water strakes | At least two points on each plate(either at each 1/4 extremity of plate or at repre- sentative areas of average corrosion) are to be measured. Where the length of the plate exceeds 6 m , two points per 6 m are to be gauged additionally. Where plates cross ballast/cargo tank boundaries separate measurements for the area of plating in way of each type of tank are to be taken. |

Selected internal structures: Selected internal structure such as floors and longitudinals, transverse frames, web frames, deck beams, girders | The internal structural members to be measured in each space internally surveyed are to be 1. at least 10% outside the cargo (length) area, 2. at least 20% within the cargo (length) area. (For oil tankers, chemical tankers or double hull oil tankers subject to the enhanced survey programme see Fig 1 and Fig 2, for single skin or double skin bulk carriers see Fig 6, for other ships see Fig 7) |

130 Guidance Relating to the Rules for the Classification of Steel Ships 2015

![]()

Pt 1 Classification and Surveys

Annex 1-5 Thickness Measurement Method for Hull Structural Member Pt 1, Annex 1-5

![]()

Table 3-1 Location and number of thickness measuring points - Non-CSR Ships (continued)

Items | Location and number of thickness measuring points |

Selected side shell frames in cargo holds for single skin bulk carriers or general dry cargo ships | 1. 25% of frames: one out of four frames is to be chosen preferably throughout the car- go hold length on each side. 2. "Selected frames" means at least 3 frames on each side of cargo holds. (For single skin bulk carriers see Fig 6, for general dry cargo ships see Fig 7) |

Transverse webs in ballast tanks for single skin bulk carriers, double skin bulk carriers or general dry cargo ships | One of the representative tanks of each type (i.e. topside or hopper or side tank) is to be chosen in the forward part. (For single skin or double skin bulk carriers see Fig 6, for general dry cargo ships see Fig 7) |

Transverse frames in double skin tanks for double skin bulk carriers | 25% of transverse frames: one out of four transverse frames is to be chosen preferably throughout the double skin tank length. (See Fig 8) |

Transverse bulkheads | 1. For oil tankers, chemical tankers or double hull oil tankers subject to the enhanced survey programme: See Fig 1 and Fig 2 2. For single skin bulk carriers, double skin bulk carriers or general dry cargo ships (See Fig 9 to Fig 11) (1) Transverse bulkheads in cargo holds - Includes bulkheads plating, stiffeners and girders, including internal structure of upper and lower stools, where fitted. - Two selected bulkheads : one is to be the bulkhead between the two foremost cargo holds and the second may be chosen in other positions (2) One transverse bulkhead in each cargo hold - The Close-up Survey and related thickness measurements are to be carried out on one side of the bulkhead; the side is to be chosen based on the outcome of the Overall Survey of both sides. In the event of doubt, the Surveyor may also require (possibly partial) Close-up Survey and related thick- ness measurements on the other side. (3) Transverse bulkheads in one ballast tank - The ballast tank is to be chosen based on the history of ballasting among those prone to have the most severe conditions. |

Cargo hold hatch covers and coamings | See Fig 12 |

(NOTES) 1. 2. X mark : means the point to be measured. | |

Guidance Relating to the Rules for the Classification of Steel Ships 2015 131

![]()

Pt 1 Classification and Surveys

Annex 1-5 Thickness Measurement Method for Hull Structural Member Pt 1, Annex 1-5

![]()

Table 3-1 Location and number of thickness measuring points - Non-CSR Ships (continued)

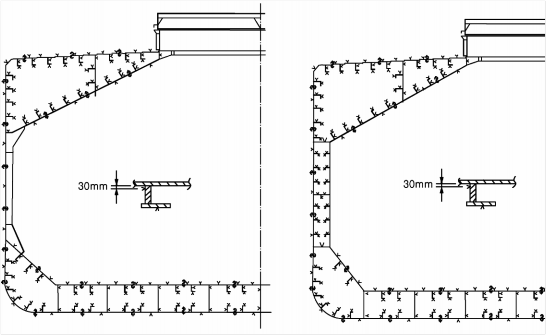

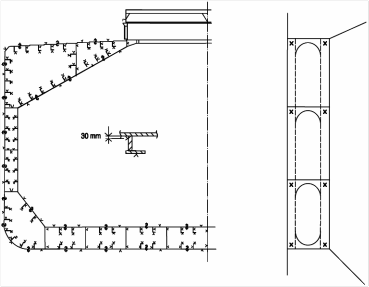

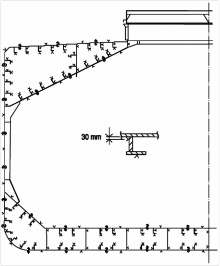

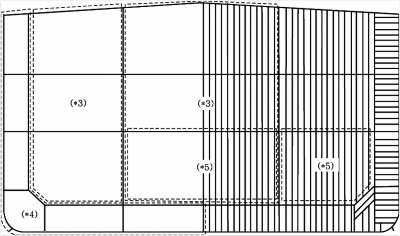

Fig 1 Locations of measurements of oil tankers and chemical tankers

132 Guidance Relating to the Rules for the Classification of Steel Ships 2015

Pt 1 Classification and Surveys

Annex 1-5 Thickness Measurement Method for Hull Structural Member Pt 1, Annex 1-5

![]()

Table 3-1 Location and number of thickness measuring points - Non-CSR Ships (continued)

Fig 2 Locations of measurements of double hull oil tankers

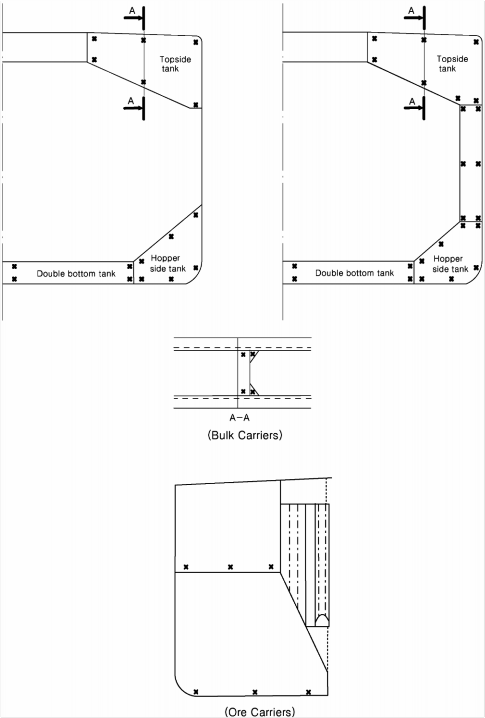

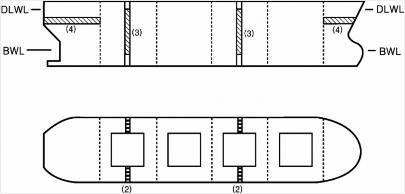

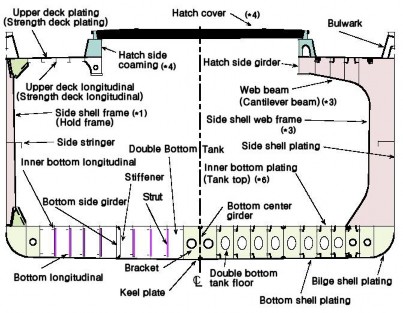

Fig 3 Locations of measurements on transverse section of single skin or double skin bulk carriers

Guidance Relating to the Rules for the Classification of Steel Ships 2015 133

Pt 1 Classification and Surveys

Annex 1-5 Thickness Measurement Method for Hull Structural Member Pt 1, Annex 1-5

![]()

Table 3-1 Location and number of thickness measuring points - Non-CSR Ships (continued)

Fig 4 Locations of measurements on transverse section of general dry cargo ships

(Notes) It may also apply to other type of transverse section.

Fig 5 Locations of measurements on transverse section of general ships

134 Guidance Relating to the Rules for the Classification of Steel Ships 2015

Pt 1 Classification and Surveys

Annex 1-5 Thickness Measurement Method for Hull Structural Member Pt 1, Annex 1-5

![]()

Table 3-1 Location and number of thickness measuring points - Non-CSR Ships (continued)

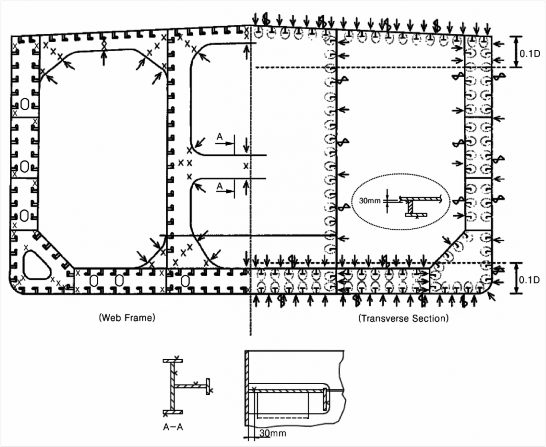

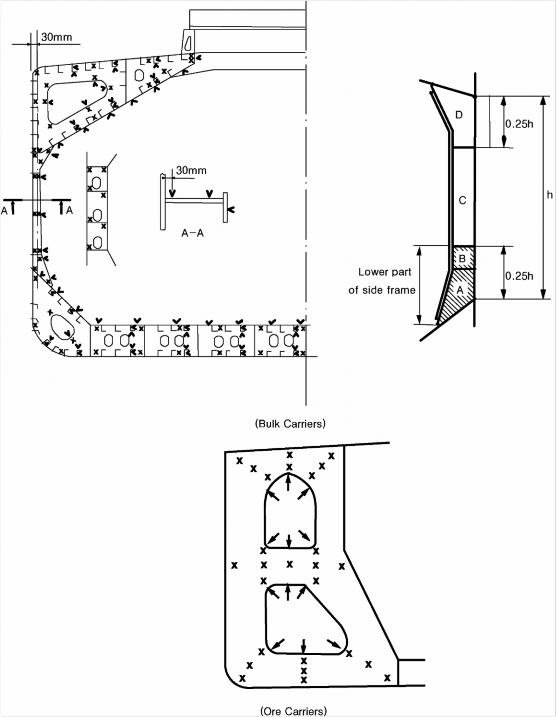

(Notes) The gauging pattern for web plating is to be a three point pattern for zones A, C and D, and a two point

pattern for zone B. The gauging report is to reflect the average reading. The average reading | is | to | be |

compared with the allowable thickness. If the web plating has general corrosion the this pattern | is | to | be |

expanded to a five point pattern. |

Fig 6 Locations of measurements on structural members in cargo holds and ballast tanks of single skin or double skin bulk carriers

Guidance Relating to the Rules for the Classification of Steel Ships 2015 135

Pt 1 Classification and Surveys

Annex 1-5 Thickness Measurement Method for Hull Structural Member Pt 1, Annex 1-5

![]()

Table 3-1 Location and number of thickness measuring points - Non-CSR Ships (continued)

(Notes) It may also apply to other ship types.

Fig 7 Locations of measurements on selected internal structural members

Fig 8 Locations of measurements on transverse frame in double skin tank of double skin bulk carriers

136 Guidance Relating to the Rules for the Classification of Steel Ships 2015

Pt 1 Classification and Surveys

Annex 1-5 Thickness Measurement Method for Hull Structural Member Pt 1, Annex 1-5

![]()

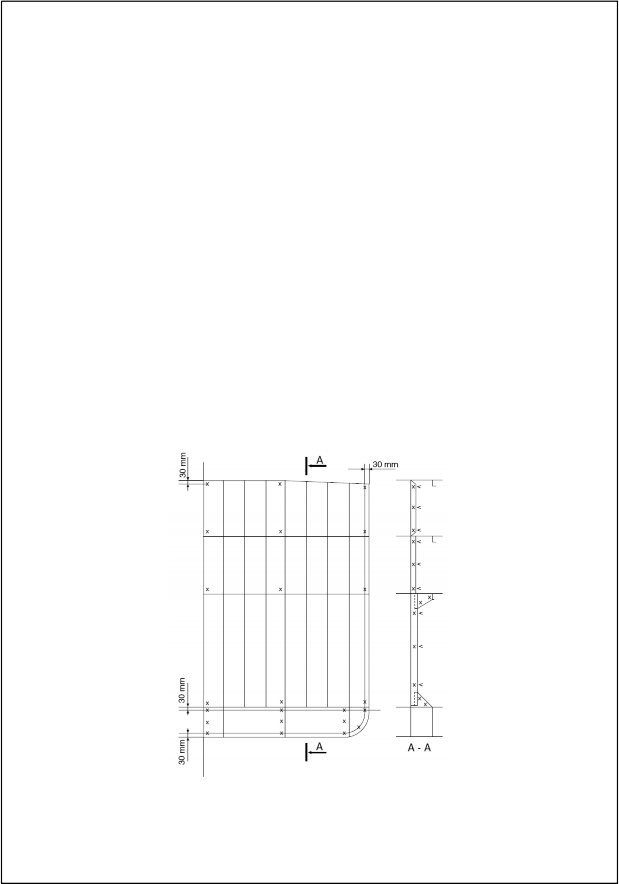

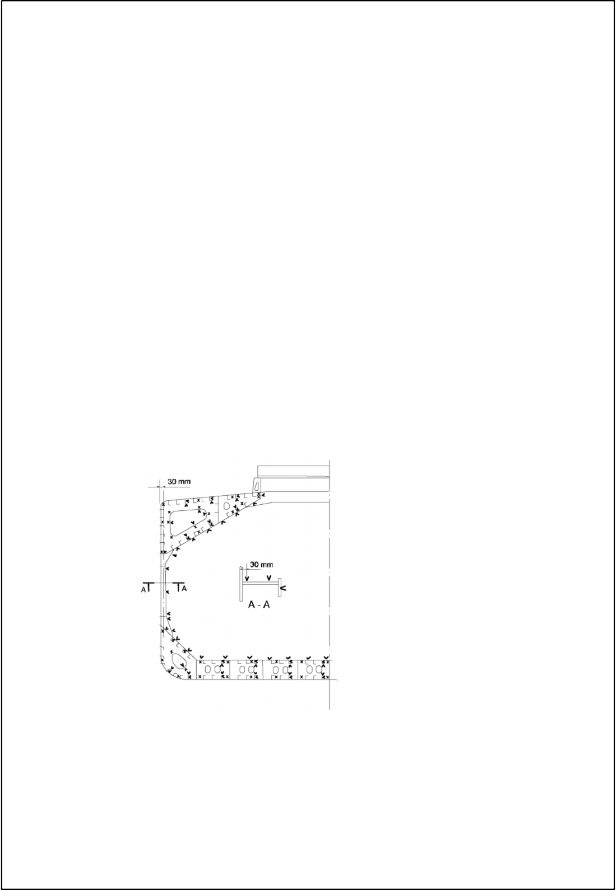

Table 3-1 Location and number of thickness measuring points - Non-CSR Ships (continued)

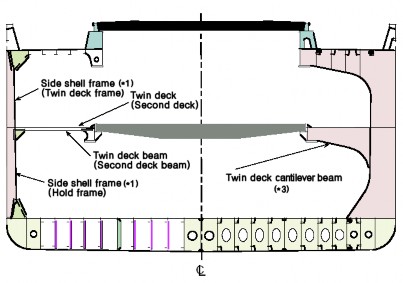

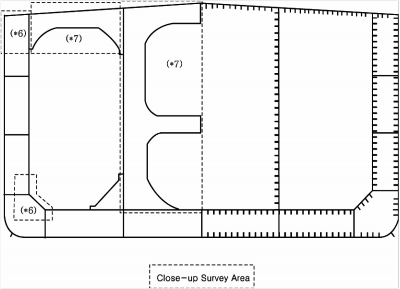

Fig 9 Locations of measurements on cargo hold transverse bulkheads of single skin or double skin bulk carriers

(Notes)

1. Cargo hold bulkhead/watertight floor plating to be measured as per main view.

2. One stiffener out of three to be measured as per view A-A.

3. It may also apply to other ship types.

Fig 10 Locations of measurements on transverse bulkheads of general dry cargo ships

Guidance Relating to the Rules for the Classification of Steel Ships 2015 137

Pt 1 Classification and Surveys

Annex 1-5 Thickness Measurement Method for Hull Structural Member Pt 1, Annex 1-5

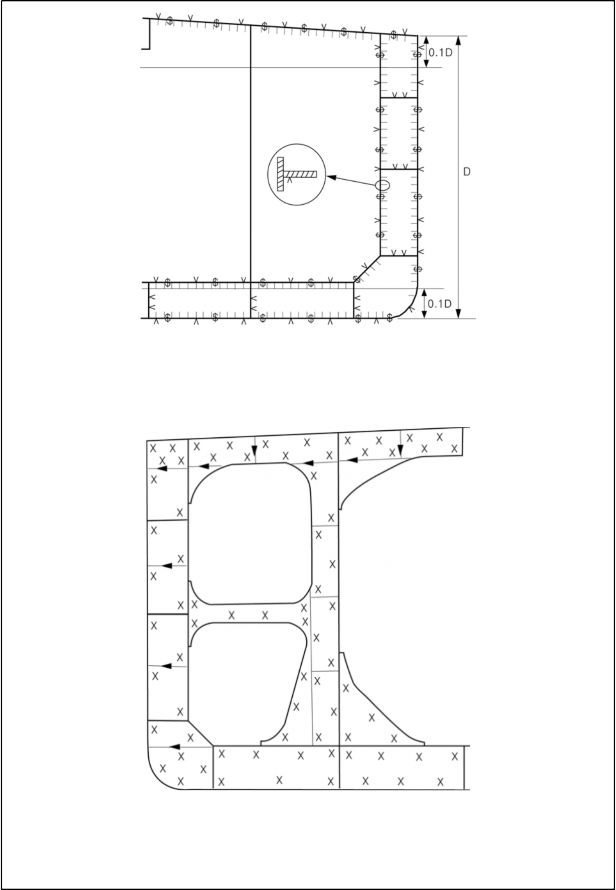

![]()

Table 3-1 Location and number of thickness measuring points - Non-CSR Ships (continued)

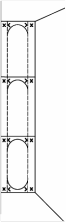

(Notes) Measurements to be taken in each vertical section as per view A-A.

Fig 11 Locations of measurements on transverse bulkheads in topside, hopper, double hull and double bottom ballast tanks of single skin or double skin bulk carriers

138 Guidance Relating to the Rules for the Classification of Steel Ships 2015

Pt 1 Classification and Surveys

Annex 1-5 Thickness Measurement Method for Hull Structural Member Pt 1, Annex 1-5

![]()

Table 3-1 Location and number of thickness measuring points - Non-CSR Ships (continued)

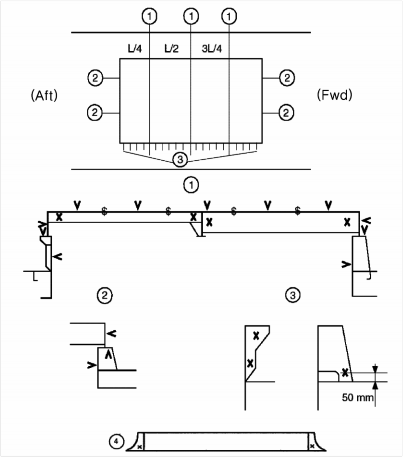

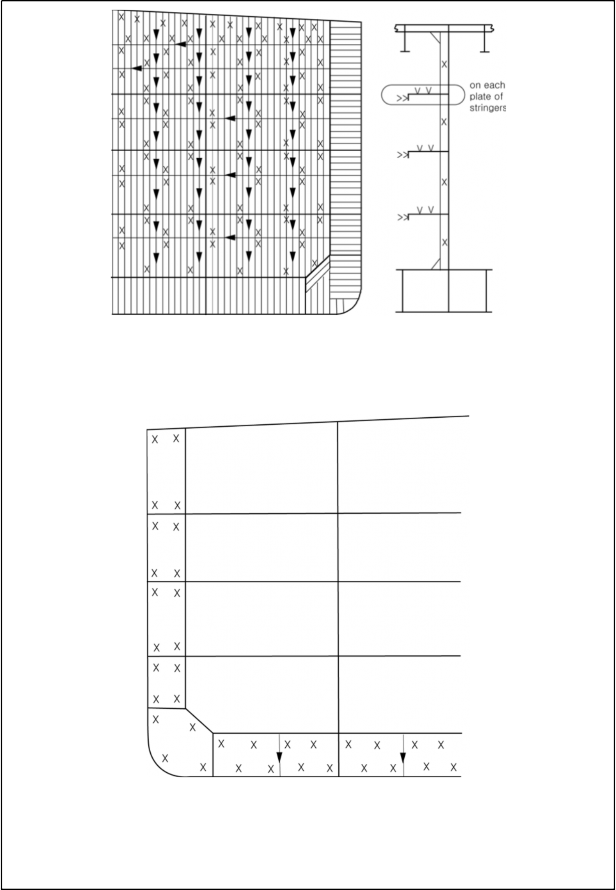

(Notes)

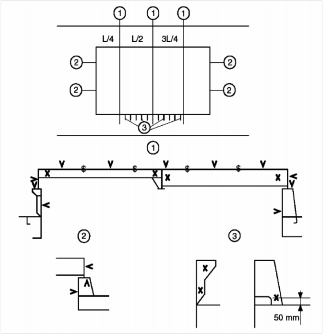

➀ For each hatch covers, three sections at L/4, L/2 and 3L/4 of hatch cover length, including:

- one measurement of each hatch cover plate and skirt plate

- measurements of adjacent beams or girder(including stiffeners)

- one measurement of coaming plates and coaming flange, each side

➁ For each hatch covers, one measurement of hatch cover skirt plate, coaming plate and coaming flange on both ends

➂ One measurement of one out of three hatch coaming brackets and bars, on both sides and both ends

➃ One measurement of each hatch coaming end bracket

Fig 12 Locations of measurements on hatch covers and coamings

Guidance Relating to the Rules for the Classification of Steel Ships 2015 139

Pt 1 Classification and Surveys

Annex 1-5 Thickness Measurement Method for Hull Structural Member Pt 1, Annex 1-5

![]()

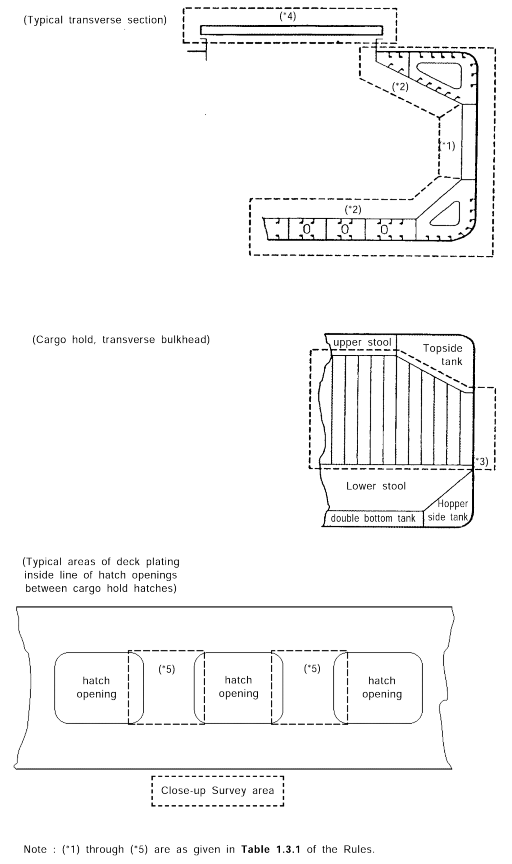

Table 3-2 Location and number of thickness measuring points - CSR Ships

Table 3-2 is to be applied to vessels built under IACS Common Structural Rules(Pt 11, Pt 12 or Pt 13)

(i.e. CSR Ships).

1) CSR bulk carriers

Items | location and number of thickness measuring points | Figure reference |

Selected plates on deck, tank top, bottom, double bottom and wind-and-water area | "Selected" means at least a single point on one out of three plates, to be chosen on representative areas of average corro- sion | |

All deck, tank top and bot- tom plates and wind-and-water strakes | At least two points on each plate to be taken either at each 1/4 extremity of plate or at representative areas of average corrosion | |

Transverse section | - For single skin bulk carriers : A transverse section includes all longitudinal members such as plating, longitudinals and girders at the deck, side, bottom, inner bottom and hopper side plating, longitudinal bulkhead and bottom plating in top wing tanks. - For double skin bulk carriers : A transverse section includes all longitudinal members such as plating, longitudinals and girders at the deck, side, bottom, inner bottom and hopper sides, inner sides and top wing inner sides. | Fig 1 |

All cargo hold hatch cov- ers and coamings | Including plates and stiffeners | Locations of points are given in Fig 2 |

Transverse section of deck plating outside line of car- go hatch openings | Two single points on each deck plate (to be taken either at each 1/4 extremity of plate or at representative areas of aver- age corrosion) between the ship sides and hatch coamings in the transverse section concerned | |

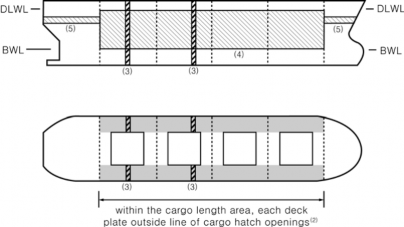

All deck plating and under deck structure inside line of hatch openings between cargo hold hatches | "All deck plating" means at least two points on each plate to be taken either at each 1/4 extremity of plate or at repre- sentative areas of average corrosion. "Underdeck structure": at each short longitudinal girder: three points for web plating(fwd/middle/aft), single point for face plate, one point for web plating and one point for face plat- ing of transverse beam in way. At each ends of transverse beams, one point for web plating and one point for face plat- ing | Extent of areas is shown in Annex 1-6, 1 (2) or (6) of the Guidance Location of points are given in Fig 6 |

140 Guidance Relating to the Rules for the Classification of Steel Ships 2015

![]()

Pt 1 Classification and Surveys

Annex 1-5 Thickness Measurement Method for Hull Structural Member Pt 1, Annex 1-5

![]()

Table 3-2 Location and number of thickness measuring points - CSR Ships (continued)

Items | location and number of thickness measuring points | Figure reference |

Single skin bulk carriers: Selected side shell frames in cargo holds for single skin bulk carriers | Includes side shell frame, upper and lower end attachments and adjacent shell plating. 25% of frames: one out of four frames should preferably be chosen throughout the cargo hold length on each side. 50% of frames: one out of two frames should preferably be chosen throughout the cargo hold length on each side. "Selected frames" means at least 3 frames on each side of cargo holds | Extent of areas is shown in Annex 1-6, 1 (2) or (6) of the Guidance Locations of points are given in Fig 3 |

Double skin bulk carriers: Transverse frame in dou- ble skin tank | Fig 1 | |

Transverse bulkheads in cargo holds | Includes bulkhead plating, stiffeners and girders, including in- ternal structure of upper and lower stools, where fitted. Two selected bulkheads: one is to be the bulkhead between the two foremost cargo holds and the second may be chosen in other positions | Areas of measure- ments are shown in Annex 1-6, 1 (2) or (6) of the Guidance Locations of points are given in Fig 4 |

One transverse bulkhead in each cargo hold | This means that the Close-up Survey and related thickness measurements are to be performed on one side of the bulk- head; the side is to be chosen based on the outcome of the overall survey of both sides. In the event of doubt, the Surveyor may also require (possibly partial) Close-up Survey and related thickness measurements on the other side | Areas of measure- ments are shown in Annex 1-6, 1 (2) or (6) of the Guidance Locations of points are given in Fig 4 |

Transverse bulkheads in one topside, hopper and double bottom ballast tank | Includes bulkhead and stiffening systems. The ballast tank is to be chosen based on the history of bal- lasting among those prone to have the most severe conditions | Locations of points are given in Fig 5 |

Transverse webs in ballast tanks | Includes web plating, face plates, stiffeners and associated plating and longitudinals. One of the representative tanks of each type (i.e. topside or hopper or side tank) is to be chosen in the forward part | Areas of measure- ments are shown in Annex 1-6, 1 (2) or (6) of the Guidance Locations of points are given in Fig 3 |

(NOTES) 1. 2. × mark : means the point to be measured. | ||

Guidance Relating to the Rules for the Classification of Steel Ships 2015 141

![]()

Pt 1 Classification and Surveys

Annex 1-5 Thickness Measurement Method for Hull Structural Member Pt 1, Annex 1-5

![]()

Table 3-2 Location and number of thickness measuring points - CSR Ships (continued)

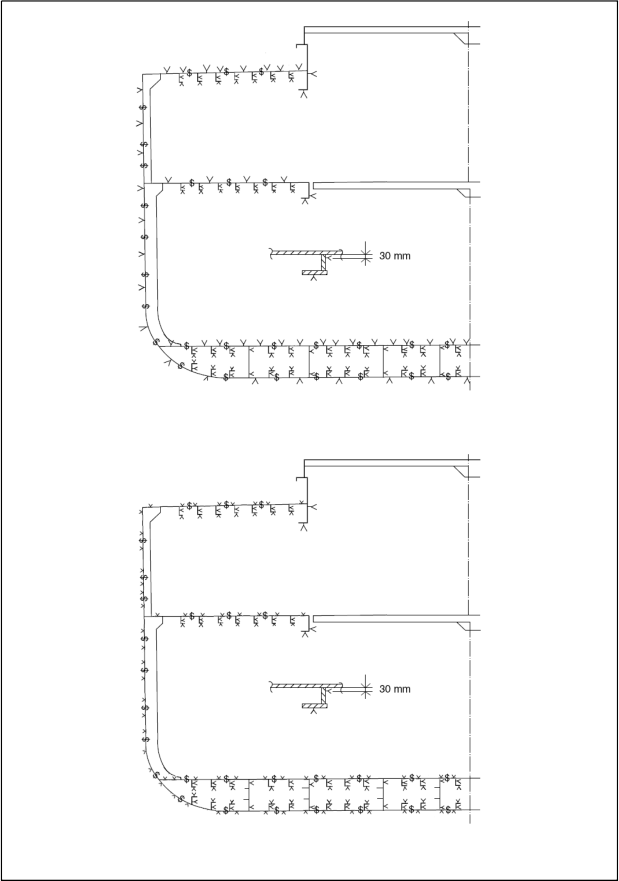

Single skin bulk carriers

Double skin bulk carriers

(Notes) Measurements are to be taken on both port and starboard sides of the selected transverse section.

Fig 1 Locations of measurements on transverse section of single skin or double skin bulk carriers

142 Guidance Relating to the Rules for the Classification of Steel Ships 2015

Pt 1 Classification and Surveys

Annex 1-5 Thickness Measurement Method for Hull Structural Member Pt 1, Annex 1-5

![]()

Table 3-2 Location and number of thickness measuring points - CSR Ships (continued)

(Notes)

1. Three sections at L/4, L/2, 3L/4 of hatch cover length, including: one measurement of each hatch cover plate and skirt plate measurements of adjacent beams and stiffeners

one measurement of coaming plates and coaming flange, each side

2. Measurements of both ends of hatch cover skirt plate, coaming plate and coaming flange

3. One measurement(two points for web plate and one point for face plate) of one out of three hatch coam- ing brackets and bars, on both sides and both ends

Fig 2 Locations of measurements on hatch covers and coamings

Guidance Relating to the Rules for the Classification of Steel Ships 2015 143

Pt 1 Classification and Surveys

Annex 1-5 Thickness Measurement Method for Hull Structural Member Pt 1, Annex 1-5

![]()

Table 3-2 Location and number of thickness measuring points - CSR Ships (continued)

(Notes) The gauging pattern for web plating is to be a three point pattern for zones A, C and D, and a two point pattern for zone B (see figure). The gauging report is to reflect the average reading. The average reading is to be compared with the allowable thickness. If the web plating has general corrosion then this pattern is to be expanded to a five point pattern.

Single skin bulk carriers

Double skin bulk carriers

Fig 3 Locations of measurements on structural members in cargo holds and ballast tanks of single skin bulk carriers and in ballast tanks(topside or hopper or side tank) of double skin bulk carriers

144 Guidance Relating to the Rules for the Classification of Steel Ships 2015

Pt 1 Classification and Surveys

Annex 1-5 Thickness Measurement Method for Hull Structural Member Pt 1, Annex 1-5

![]()

Table 3-2 Location and number of thickness measuring points - CSR Ships (continued)

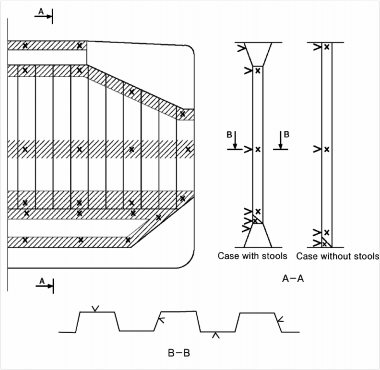

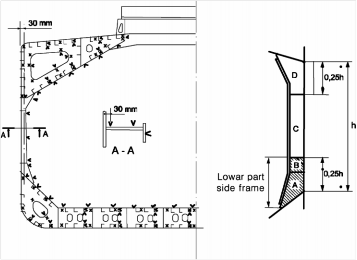

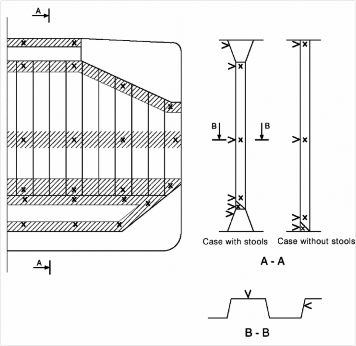

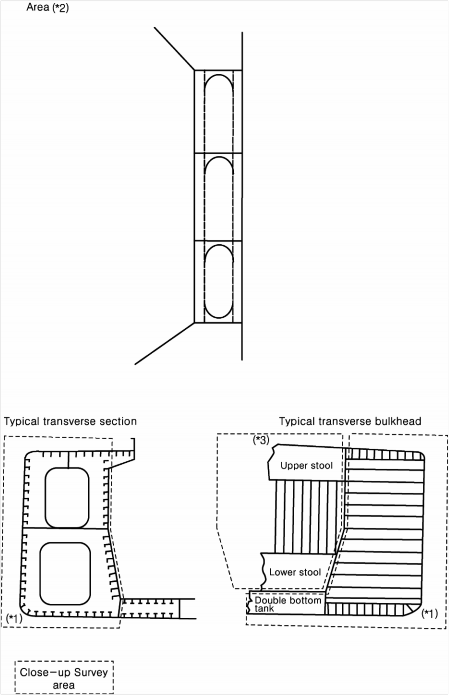

(Notes) Measurements to be taken in each shaded area as per views A-A and B-B.

Additional measurements to internal structure of upper and lower stools to be added, e.g. two points in the upper and two points in the lower stools to be indicated in section A-A.

Fig 4 Location of measurements on cargo hold transverse bulkheads of single skin or double skin bulk carriers

Guidance Relating to the Rules for the Classification of Steel Ships 2015 145

Pt 1 Classification and Surveys

Annex 1-5 Thickness Measurement Method for Hull Structural Member Pt 1, Annex 1-5

![]()

Table 3-2 Location and number of thickness measuring points - CSR Ships (continued)

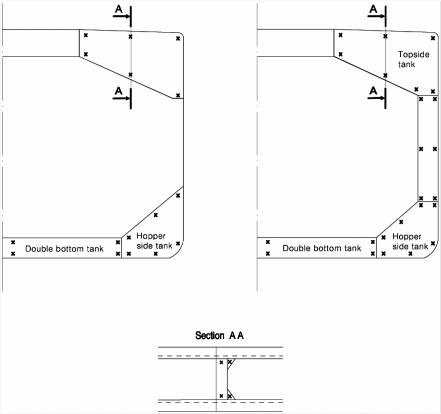

(Notes) Measurements to be taken in each vertical section as per view A-A

Two additional measurements to internal structure of double bottom tank to be added at midspan.

Fig 5 Locations of measurements on transverse bulkheads of topside, hopper, double hull and double bottom ballast tanks of single skin or double skin bulk carriers

146 Guidance Relating to the Rules for the Classification of Steel Ships 2015

Pt 1 Classification and Surveys

Annex 1-5 Thickness Measurement Method for Hull Structural Member Pt 1, Annex 1-5

![]()

Table 3-2 Location and number of thickness measuring points - CSR Ships (continued)

Fig 6 Locations of measurements on underdeck structure

Guidance Relating to the Rules for the Classification of Steel Ships 2015 147

Pt 1 Classification and Surveys

Annex 1-5 Thickness Measurement Method for Hull Structural Member Pt 1, Annex 1-5

![]()

Table 3-2 Location and number of thickness measuring points - CSR Ships (continued)

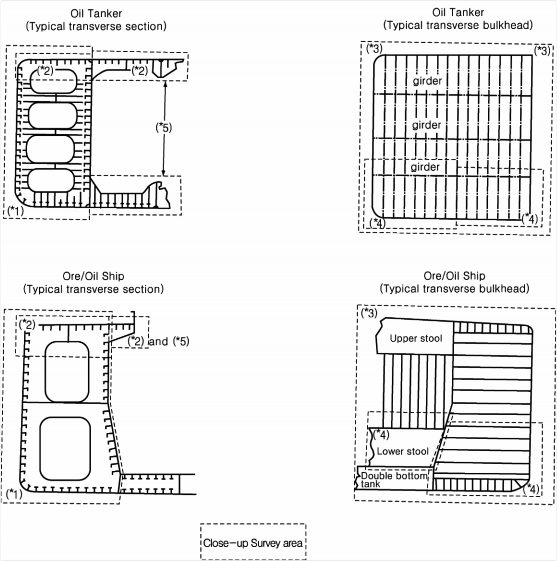

2) CSR double hull oil tankers

Items | location and number of thickness measuring points | Figure reference |

Selected plates | "Selected" means at least a single point on one out of three plates, to be chosen on representative areas of average corro- sion | |

Deck, bottom plates and wind-and-water strakes | At least two points on each plate to be taken either at each 1/4 extremity of plate or at representative areas of average corrosion | |

Transverse section | Measurements to be taken on all longitudinal members such as plating, longitudinals and girders at the deck, side, bottom, longitudinal bulkheads, inner bottom and hopper. One point to be taken on each plate. Both web and flange to be measured on longitudinals, if applicable. For tankers older than 10 years of age: within 0.1D (where D is the ship’s moulded depth) of the deck and bottom at each transverse section to be measured, every longitudinal and girder is to be measured on the web and face plate, and every plate is to be measured at one point between longitudinals. | Fig 1 |

Transverse rings3) in cargo and ballast tanks | At least two points on each plate in a staggered pattern and two points on the corresponding flange where applicable. Minimum 4 points on the first plate below deck. Additional points in way of curved parts. At least one point on each of two stiffeners between stringers / longitudinal girders. | Fig 2 |

148 Guidance Relating to the Rules for the Classification of Steel Ships 2015

![]()

Pt 1 Classification and Surveys

Annex 1-5 Thickness Measurement Method for Hull Structural Member Pt 1, Annex 1-5

![]()

![]()

Table 3-2 Location and number of thickness measuring points - CSR Ships (continued)

Items | location and number of thickness measuring points | Figure reference |

Transverse bulkheads in cargo tanks | At least two points on each plate. Minimum 4 points on the first plate below main deck. At least one point on every third stiffener to be taken be- tween each stringer. At least two points on each plate of stringers and girders, and two points on the corresponding flange. Additional points in way of curved part. Two points of each diaphragm plate of stools if fitted. | Fig 3 |

Transverse bulkheads in ballast tanks | At least 4 points on plates between stringers / longitudinal girders, or per plate if stringers / girders not fitted. At least two points on each plate of stringers and girders, and two points on the corresponding flange. Additional points in way of curved part. At least one point on two stiffeners between each stringer / longitudinal girder. | Fig 4 |

Adjacent structural mem- bers | On adjacent structural members one point per plate and one point on every third stiffener / longitudinal. | |

(NOTES) 1. mark : means the location to be measured. 2. × mark : means the point to be measured. 3. Transverse rings means all transverse material appearing in a cross-section of the ship's hull, in way of a dou- ble bottom floor, vertical web and deck transverse (definition from IACS Common Structural Rules for Double Hull Oil Tankers(Pt 12 or Pt 13 of the Rules). | ||

Guidance Relating to the Rules for the Classification of Steel Ships 2015 149

![]()

Pt 1 Classification and Surveys

Annex 1-5 Thickness Measurement Method for Hull Structural Member Pt 1, Annex 1-5

![]()

Table 3-2 Location and number of thickness measuring points - CSR Ships (continued)

Fig 1 Locations of measurements on transverse section of double hull oil tankers

Fig 2 Locations of measurements on transverse rings in cargo and ballast tanks of double hull oil tankers

150 Guidance Relating to the Rules for the Classification of Steel Ships 2015

Pt 1 Classification and Surveys

Annex 1-5 Thickness Measurement Method for Hull Structural Member Pt 1, Annex 1-5

![]()

Table 3-2 Location and number of thickness measuring points - CSR Ships (continued)

Fig 3 Locations of measurements on transverse bulkheads in cargo tanks of double hull oil tankers

Fig 4 Locations of measurements on transverse bulkheads in ballast tanks of double hull oil tankers

Guidance Relating to the Rules for the Classification of Steel Ships 2015 151

Pt 1 Classification and Surveys

Annex 1-5 Thickness Measurement Method for Hull Structural Member Pt 1, Annex 1-5

![]()

Table 4 Extent of thickness measurements at Special Survey - General Ships

No. of Special Survey | Extent and location of measurement |

Special Survey No. 1 | (1) Suspect areas throughout the vessel |

Special Survey No. 2 |

(1) Suspect areas throughout the vessel (2) One transverse section of deck plating in way of a cargo space within the amidships 0.5 |

Special Survey No. 3 |

(1) Suspect areas throughout the vessel (2) Two transverse sections within the amidships 0.5 (3) All cargo hold hatch covers and coamings(plating and stiffeners) (4) Internals in forepeak and afterpeak tanks (5) All transverse bulkheads in all cargo tanks8) (6) All transverse bulkheads in all ballast tanks8) |

152 Guidance Relating to the Rules for the Classification of Steel Ships 2015

![]()

Pt 1 Classification and Surveys

Annex 1-5 Thickness Measurement Method for Hull Structural Member Pt 1, Annex 1-5

![]()

![]()

Table 4 Extent of thickness measurements at Special Survey - General Ships (continued)

No. of Special Survey | Extent and location of measurement |

Special Survey No. 4 and Subsequent |

(1) Suspect areas throughout the vessel (2) A minimum of three transverse sections in way of cargo spaces within the amidships 0.5 5), 6), 7) (3) All cargo hold hatch covers and coamings(plating and stiffeners) (4) Internals in forepeak and afterpeak tanks (5) All exposed main deck plating full length (6) Representative exposed superstructure deck plating(poop, bridge and forecastle deck) (7) Lowest strake and strakes in way of 'tween decks of all transverse bulkheads in cargo spaces together with internals in way (8) All wind and water strakes, port and starboard, full length (9) All keel plates full length. Also, additional bottom plates in way of cofferdams, machi- nery space and aft end of tanks (10) Plating of seachests. Shell plating in way of overboard discharges as considered nec- essary by the attending Surveyor (11) All transverse bulkheads and one web frame ring in all cargo tanks8) (12) All transverse bulkheads and all web frame ring in all ballast tanks8) |

(NOTES) Thickness gaugings for deck plates Thickness gaugings for side shell plates Thickness gaugings for the transverse section(applied for plates only) Thickness gaugings for the transverse section(including longitudinal members, for trans- versely framed vessels including adjacent frames and their end connections in way of transverse sections) 1) In application to this table, General Ships means ships except Other Ships in Table 1.2.4, 2. of the Rules. 2) Thickness measurement locations are to be selected to provide the best representative sampling of areas likely to be most exposed to corrosion, considering cargo and ballast history and arrangement and con- dition of protective coatings. 3) Thickness measurements of internals may be specially considered by the Surveyor if the hard protective coating is in GOOD condition. 4) For ships more than 100 meters in length, at Special Survey No. 3, thickness measurements of exposed deck plating within amidship 0.5 may be required. 5) For ships less than 100 meters in length, the number of transverse sections required at Special Survey No. 3 may be reduced to one (1), and the number of transverse sections required at Special Survey No. 4 and subsequent may be reduced to two (2). 6) For the pure car carrier, the extent of thickness measurement for transverse sections may by considered as follow: Exposed deck plates, side shell plates, bottom shell plates, inner bottom plates and longitudinal members in double bottom spaces. 7) Where the evaluation of longitudinal strength is required, all longitudinal structural members at the corre- sponding sections are to be gauged. 8) This requirement is to be applied only for tankers(including barges) for liquid cargo. | |

![]()

![]()

Guidance Relating to the Rules for the Classification of Steel Ships 2015 153

![]()

Pt 1 Classification and Surveys

Annex 1-5 Thickness Measurement Method for Hull Structural Member Pt 1, Annex 1-5

![]()

Table 5 Extent of thickness measurements at Special Survey - Other Ships

No. of Special Survey | Extent and location of measurement |

Special Survey No. 1 | (1) Suspect areas throughout the vessel |

Special Survey No. 2 |

(1) Suspect areas throughout the vessel (2) One transverse section of deck plating5), side shell plating and bottom plating within the amidships 0.5 |

Special Survey No. 3 |

(1) Suspect areas throughout the vessel (2) Two transverse sections of deck plating5), side shell plating and bottom plating within the amidships 0.5 (3) Internals in forepeak and afterpeak tanks |

154 Guidance Relating to the Rules for the Classification of Steel Ships 2015

![]()

Pt 1 Classification and Surveys

Annex 1-5 Thickness Measurement Method for Hull Structural Member Pt 1, Annex 1-5

![]()

Table 5 Extent of thickness measurements at Special Survey - Other Ships (continued)

No. of Special Survey | Extent and location of measurement |

Special Survey No. 4 and Subsequent |

(1) Suspect areas throughout the vessel (2) Two transverse sections of side shell plating within the amidships 0.5 (3) Full length, all exposed main deck plating5) (4) Full length, representative exposed superstructure deck plating(poop, bridge and forecastle deck) (5) Full length, selected wind and water strakes (6) Full length, bottom plating and flat keel plating (7) Internals in forepeak and afterpeak tanks |

(NOTES) Thickness gaugings for deck plates Thickness gaugings for side shell plates Thickness gaugings for the transverse section(applied for plates only) 1) In application to this table, Other Ships means the ship specified as follows except Special Purpose Ship - Waste in Annex 1-1, 1.1 of the Guidance. - the ship type 12, 13 - the ship less than 500 GT and not engaged on international voyages among ship type 15, 16, 17, 19, 20 and 26 to 30. 2) Thickness measurement locations are to be selected to provide the best representative sampling of area likely to be most exposed to corrosion. 3) Thickness measurements of internals may be specially considered by the Surveyor if the hard protective coating is in GOOD condition. 4) When the evaluation of longitudinal strength is required, all longitudinal structural members at the corre- sponding sections are to be gauged. 5) For fishing vessel, thickness measurement requirements in way of deck(gutter water way part and hatch coaming part) may be modified at the discretion of the Surveyor if the structure remains effectively pro- tected against corrosion by a permanent type special coating. | |

Guidance Relating to the Rules for the Classification of Steel Ships 2015 155

![]()

Pt 1 Classification and Surveys

Annex 1-5 Thickness Measurement Method for Hull Structural Member Pt 1, Annex 1-5

![]()

Table 6 Extent of thickness measurements at Special Survey - General Dry Cargo Ships

No. of Special Survey | Extent and location of measurement |

Special Survey No. 1 | (1) Suspect areas |

Special Survey No. 2 |

(1) Suspect areas (2) One transverse section of deck plating in way of a cargo length area within the amidships 0.5 (3) Measurement for general assessment and recording of corrosion pattern of those structural members subject to Close-up Survey |

Special Survey No. 3 |

(1) Suspect areas (2) Two transverse sections within the amidships 0.5 (3) Measurement for general assessment and recording of corrosion pattern of those structural members subject to Close-up Survey (4) Within the cargo length area, each deck plate outside line of cargo hatch openings (5) All wind and water strakes within the cargo length area (6) Selected wind and water strakes outside the cargo length area |

156 Guidance Relating to the Rules for the Classification of Steel Ships 2015

![]()

Pt 1 Classification and Surveys

Annex 1-5 Thickness Measurement Method for Hull Structural Member Pt 1, Annex 1-5

![]()

![]()

Table 6 Extent of thickness measurements at Special Survey - General Dry Cargo Ships (continued)

No. of Special Survey | Extent and location of measurement |

Special Survey No. 4 and Subsequent |

(1) Suspect areas (2) Within the cargo length area, a minimum of three transverse sections within the amidships 0.5 2) (3) Within the cargo length area, each deck plate outside line of cargo hatch openings (4) Within the cargo length area, each bottom plate, including lower turn of bilge (5) Within the cargo length area, duct keel or pipe tunnel plating and internals (6) Measurement for general assessment and recording of corrosion pattern of those structural members subject to Close-up Survey (7) All wind and water strakes full length |

(NOTES) Thickness gaugings for deck plates Thickness gaugings for side shell plates Thickness gaugings for the transverse section(applied for plates only) Thickness gaugings for the transverse section(including longitudinal members, for transversely framed vessels including adjacent frames and their end connections in way of transverse sections) 1) Thickness measurement locations are to be selected to provide the best representative sampling of area likely to be most exposed to corrosion, considering cargo and ballast history and arrangement and con- dition of protective coatings. 2) For ships less than 100 meters in length, the number of transverse sections required at Special Survey No. 3 may be reduced to one and the number of transverse sections at Special Survey No. 4 and sub- sequent surveys may be reduced to two. | |

![]()

Guidance Relating to the Rules for the Classification of Steel Ships 2015 157

![]()

Pt 1 Classification and Surveys

Annex 1-5 Thickness Measurement Method for Hull Structural Member Pt 1, Annex 1-5

![]()

Table 7 Extent of thickness measurements at Special Survey - Liquefied Gas Carriers

No. of Special Survey | Extent and location of measurement |

Special Survey No. 1 |

(1) Suspect areas (2) One section of deck plating for the full beam of the ship within 0.5 (3) Measurement for general assessment and recording of corrosion pattern of those structural members subject to Close-up Survey |

Special Survey No. 2 |

(1) Suspect areas (2) Within the cargo area, each deck plate (3) Within the cargo area, one transverse section within 0.5 (4) Selected wind and water strakes outside the cargo area (5) Measurement for general assessment and recording of corrosion pattern of those structural members subject to Close-up Survey |

158 Guidance Relating to the Rules for the Classification of Steel Ships 2015

![]()

Pt 1 Classification and Surveys

Annex 1-5 Thickness Measurement Method for Hull Structural Member Pt 1, Annex 1-5

![]()

Table 7 Extent of thickness measurements at Special Survey - Liquefied Gas Carriers (continued)

No. of Special Survey | Extent and location of measurement |

Special Survey No. 3 |

(1) Suspect areas (2) Within the cargo area, each deck plate (3) Within the cargo area, two transverse sections1) (4) Within the cargo area, all wind and water strakes (5) Selected wind and water strakes outside the cargo area (6) Measurement for general assessment and recording of corrosion pattern of those structural members subject to Close-up Survey |

Special Survey No. 4 and Subsequent |

(1) Suspect areas (2) Within the cargo area, each deck plate (3) Within the cargo area, three transverse sections1) (4) Within the cargo area, each bottom plate (5) Within the cargo area, duct keel plating and internals (6) All wind and water strakes, full length (7) Measurement for general assessment and recording of corrosion pattern of those structural members subject to Close-up Survey |

Guidance Relating to the Rules for the Classification of Steel Ships 2015 159

![]()

Pt 1 Classification and Surveys

Annex 1-5 Thickness Measurement Method for Hull Structural Member Pt 1, Annex 1-5

![]()

![]()

Table 7 Extent of thickness measurements at Special Survey - Liquefied Gas Carriers (continued)

(NOTES)

Thickness gaugings for deck plates Thickness gaugings for side shell plates

Thickness gaugings for the transverse section(applied for plates only)

Thickness gaugings for the transverse section(including longitudinal members, for transversely framed vessels including adjacent frames and their end connections in way of transverse sec- tions)

1) At least one section is to include a ballast tank within 0.5 amidships, if any.

2) For ships having independent tanks of type C, with a midship section similar to that of a general cargo ship, the extent of thickness measurements may be increased to include the tank top plating at the discretion of the Surveyor.

3) For areas in spaces where protective coatings are found to be in GOOD condition, the extent of thickness measurements may be specially considered by the Society.

4) The Surveyor may extend the thickness measurements as deemed necessary. Where substantial corrosion is found, the extent of thickness measurements is to be increased to the satisfaction of the Surveyor.

160 Guidance Relating to the Rules for the Classification of Steel Ships 2015

![]()

Pt 1 Classification and Surveys

Annex 1-5 Thickness Measurement Method for Hull Structural Member Pt 1, Annex 1-5

![]()

Table 8 Extent of thickness measurements at Special Survey - Bulk Carriers with ESP notation

No. of

Special Survey Extent and location of measurement

Special Survey

No. 1 (1) Suspect areas

Special Survey No. 2

(1) Suspect areas

(2) Within the cargo length, two transverse sections of deck plating outside line of cargo hatch openings

(3) Wind and water strakes in way of transverse sections considered under (2) above

(4) Selected wind and water strakes outside the cargo length area

(5) Measurement for, general assessment and recording of corrosion pattern, of those structural members subject to Close-up Survey

(6) See Ch 3, 201. 1 (4) of the Rules, Pt 7, Ch 3, Sec 17 of the Rules and the separate re- quirements specified by the Society for additional thickness measurement guidelines applicable to the side shell frames and brackets on ships subject to compliance with IACS UR S31

Special Survey

No. 3 (1) Suspect areas

(2) Within the cargo length, each deck plate outside line of cargo hatch openings

(3) Within the cargo length, two transverse sections, one in the amidship area, outside line of cargo hatch openings

(4) Within the cargo length, all wind and water strakes

(5) Selected wind and water strakes outside the cargo length area

(6) Measurement for, general assessment and recording of corrosion pattern, of those structural members subject to Close-up Survey

(7) See Ch 3, 201. 1 (3) of the Rules and Annex 1-5, Table 9 of the Guidance for additional thickness measurement guidelines applicable to the vertically corrugated transverse watertight bulkhead between cargo hold Nos. 1 and 2 on ships subject to compliance with IACS URs S19 and S23

(8) See Ch 3, 201. 1 (4) of the Rules, Pt 7, Ch 3, Sec 17 of the Rules and the separate re- quirements specified by the Society for additional thickness measurement guidelines applicable to the side shell frames and brackets on ships subject to compliance with IACS UR S31

Guidance Relating to the Rules for the Classification of Steel Ships 2015 161

![]()

Pt 1 Classification and Surveys

Annex 1-5 Thickness Measurement Method for Hull Structural Member Pt 1, Annex 1-5

![]()

Table 8 Extent of thickness (continued)

measurements at Special Survey - Bulk Carriers with ESP notation

No. of Special Survey | Structural members to be measured |

Special Survey No. 4 and Subsequent |

(1) Suspect areas (2) Within the cargo length, each deck plate outside line of cargo hatch openings (3) Within the cargo length, three transverse sections, one in the amid ship area, outside line of cargo hatch openings (4) Within the cargo length, each bottom plates (5) All wind and water strakes, full length (6) Measurement for, general assessment and recording of corrosion pattern, of those structural members subject to Close-up Survey (7) See Ch 3, 201. 1 (3) of the Rules and Annex 1-5, Table 9 of the Guidance for addi- tional thickness measurement guidelines applicable to the vertically corrugated transverse wa- tertight bulkhead between cargo hold Nos. 1 and 2 on ships subject to compliance with IACS URs S19 and S23 (8) See Ch 3, 201. 1 (4) of the Rules, Pt 7, Ch 3, Sec 17 of the Rules and the separate re- quirements specified by the Society for additional thickness measurement guidelines appli- cable to the side shell frames and brackets on ships subject to compliance with IACS UR S31 |

(NOTES) Thickness gaugings for deck plates Thickness gaugings for side shell plates Thickness gaugings for the transverse section(applied for plates only) Thickness gaugings for the transverse section(including longitudinal members, for transversely framed vessels including adjacent frames and their end connections in way of transverse sections) | |

![]()

162 Guidance Relating to the Rules for the Classification of Steel Ships 2015

![]()

Pt 1 Classification and Surveys

Annex 1-5 Thickness Measurement Method for Hull Structural Member Pt 1, Annex 1-5

![]()

Table 9 Additional thickness measurements head between holds Nos. 1 and 2

of the vertically corrugated transverse watertight bulk-

Location | Vertically corrugated transverse watertight bulkhead between holds Nos. 1 and 2 |

Gauging point | 1. The gauging is to be carried out at the levels as described below. To adequately assess the scantlings of each individual vertical corrugation, each corrugation flange, webs, shedder plate and gusset plate within each of the levels given below are to be gauged. (1) Level (A) : Ships without lower stool (See Fig 1) (a) The mid-breadth of the corrugation flanges at approximately 200 mm above the line of shedder plates; (b) The middle of gusset plates between corrugation flanges, where fitted; (c) The middle of the shedder plates; (d) The mid-breadth of the corrugation webs at approximately 200 mm above the line of shedder plates. (2) Level (B) : Ships with lower stool (See Fig 2) (a) The mid-breadth of the corrugation flanges at approximately 200 mm above the line of shedder plates; (b) The middle of gusset plates between corrugation flanges, where fitted; (c) The middle of the shedder plates; (d) The mid-breadth of the corrugation webs at approximately 200 mm above the line of shedder plates. (3) Level (C) : Ships with or without lower stool (See Fig 1 or Fig 2) (a) The mid-breadth of the corrugation flanges and webs at about the mid-height of the corrugation. 2. Where the thickness changes within the horizontal levels, the thinner plate is to be gauged. |

| |

Guidance Relating to the Rules for the Classification of Steel Ships 2015 163

![]()

Pt 1 Classification and Surveys

Annex 1-5 Thickness Measurement Method for Hull Structural Member Pt 1, Annex 1-5

![]()

Table 10 Extent of thickness measurements at Special Survey - Oil Tankers with ESP notation

No. of Special Survey | Extent and location of measurement |

Special Survey No. 1 |