< Previous | Contents | Next >

Section 6 Steel Forgings

601. Steel Forgings

1. Manufacturing process

(1) The application to the requirements of 601. 3 (5), (a) of the Rules is to be in accordance with the following :

For crankshafts, where grain flow is required in the most favourable direction having regard to the mode of stressing in service, the proposed method of manufacture may require special ap-

proval by the Society. In such cases,

structure and grain flow are obtained.

(2) The application to the requirements of following :

tests may be required to demonstrate that a satisfactory

601. 3 (6) of the Rules is to be in accordance with the

These requirements apply to where gas workings are being carried out on the parts subjected to high stress such as mass removal of crankshaft. The data related to the processes (including preheating) and change of material due to working are to be submitted approval of the Society.

2. Heat treatment

The application to 601. 4 (1) of the Rules is to be in accordance with the following :

(1) The application to 601. 4 (1) of the Rules is to be in accordance with the following :

Overall length of the product is not afforded to be heat treated simultaneously, it is requested that an approval of the surveyor be obtained beforehand. In this case, one set of test specimens is to be taken from each end of the product. Degree of heterogeneity in micro structure at the boundary zone caused by such a heat treatment is to be examined by the method deemed ap- propriate by the Society and ultrasonic test.

(2) "For the purposes of this approval" referred in 601. 4 (7) of the Rules includes where surface harden forgings method is not normal or manufacturers don't have sufficient knowledge and ex- perience, etc.

3. Mechanical properties

In application to 601. 6 Note (4) of Table 2.1.84 of the Rules, the kinds and average absorbed energy for low alloys steel forgings intended to be used for important parts of machinery which

the impact test may be required are to comply with the requirements of Table 2.1.13

Guidance.

of the

Table 2.1.13 Kinds and Average Absorbed Energy for Low Alloys Steel Forgings

Grades | Low Alloys Steel forging applied | Charpy V notch Impact test | ||||||||||

Average absorbed energy(J) | ||||||||||||

L | T | |||||||||||

RSF | 600AM | - Crankshaft - Forgings for gears | 41 min. | 24 min. | ||||||||

RSF 700AM | 32 min. | 22 min. | ||||||||||

RSF 800AM | 32 min. | 20 min. | ||||||||||

RSF1000AM | 25 min. | 16 min. | ||||||||||

RSF1100AM | 21 min. | 13 min. | ||||||||||

(Note) | Impact | tests | are | to | be | carried | out | at | ambient | temperature | (18~25 | ). |

![]()

![]()

18 Guidance Relating to the Rules for the Classification of Steel Ships 2015

Pt 2 Materials and Welding

Ch 1 Materials Pt 2, Ch 1

![]()

4. Selection of test specimen

Selection of the test specimens for forgings subjected to surface hardening, except for carburizing, specified in 601. 7 (9) of the Rules and hardness test are to comply with the following requirements.

(1) Induction hardened or nitrized gears

(A) Tensile and impact test specimens

The test specimens are to be taken from the product after the final heat treatment and be- fore the surface hardening in accordance with the requirements specified in 601. 7 (3), (b) through (e) of the Rules

(B) Depth of the hardened layer

(a) In case of induction hardening

The depth of the hardened layer of the product is to be measured when the gear is produced for the first time, and tests thereafter may be dispensed with.

(b) In case of nitrization

(i) Selection of test samples

Test samples are to be made of the same material as the product having been proc- essed under the same conditions.

(ii) Size of test samples

The size of the test samples may be optional. (iii)Heat treatments of test samples

The test samples are to be heat treated and nitrized simultaneously together with the product.

(iv)Measurements of depth of hardened layer

The depth of hardened layer is to be measured every lot of same nitrization.

(2) The hardness tests of the surface hardened gears are to be dealt with as follows :

(A) The requirements for the measurement of hardness after surface hardening processes have been required related to the Shafting and Power Transmission Systems in Pt 5, Ch 3 of the Rules, and the measured hardness value is to be approved by the Society in relation of the approval of the manufacturing processes.

(B) In case where the measurements of hardness for every forged products are difficult owing to their sizes and shapes, the hardness may be measured at appropriate locations considered to be representative in respect to the value of hardness resulted from the approval tests for the manufacturing processes referred to in (A) above.

5. Surface inspection

The requirements specified in 601. 8 of the Rules are to be dealt with as follows :

(1) The surface inspection of steel forgings is to comply with the Annex 2-5, 2.

6. Non-destructive inspection

(1) Non-destructive inspection of steel forgings specified in 601. 10 (1) and (2) of the Rules are to be dealt with as follows:

(A) The non-destructive inspection of steel forgings are to comply with the Annex 2-5, 2 and

3.

(2) "other non-destructive inspections considered adequate by the Society" referred in 601. 10 (4) of the Rules means the non-destructive considering materials, shapes and stress conditions, etc.

(3) "deemed necessary by the Society" referred in 601. 10 (5) of the Rules means the steel forg- ing is difficult to detect a defect by visual inspection.

(4) "the non-destructive inspections considered adequate by the Society" referred in 601. 10 (6) of

the Rules means the non-destructive considering the welded part's materials, shapes and stress conditions, etc.

7. Repair of defects

The application to 601. 11 (4) of the Rules is to be accordance with the following:

![]()

Guidance Relating to the Rules for the Classification of Steel Ships 2015 19

Pt 2 Materials and Welding

Ch 1 Materials Pt 2, Ch 1

![]()

(1) Repair by welding in order of correct shapes for the portions not subjected to high stress may be accepted.

8. Additional requirements for crank shafts

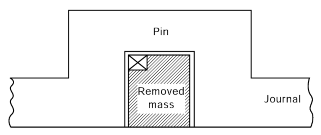

(1) In 601. 14 (1) of the Rules, where the heat treatments of the crank throws of solid crank shafts are carried out without mass removal, one set of test specimens are to be taken from the removed mass of the central crank throw at the part neighboring the pin, as shown in Fig

2.1.4 of the Guidance after the heat treatment.

Fig 2.1.4 Location of Test Specimens

(2) In relation to the tests for semibuilt-up crank throws specified in 601. 14 (2) of the Rules, fol- lowing requirements are to be complied with.

(A) Test specimens are to be taken, in general, one set from each arm in the longitudinal

direction.

(B) In case where either the process of manufacturing those approved are intended to be changed or cranks larger than ever approved are intended to be manufactured, the tests in- structed by the Society are to be newly carried out.

603. Steel forgings for

1. Application

(1) In application to

chains

603. 1 (2) of the Rules, Steel forgings for offshore mooring chain are to

comply with Annex 2-9, 3 of this guidance.

(2) In application to 603. 1 (4) of the Rules, the term "considered by the Society" means the ac- ceptance in accordance with Pt 1, Ch 1, 104. or 105. of the Guidance.

![]()

20 Guidance Relating to the Rules for the Classification of Steel Ships 2015

Pt 2 Materials and Welding

Ch 1 Materials Pt 2, Ch 1

![]()