< Previous | Contents | Next >

Annex 2-9 Offshore mooring chain

1. Application

These requirements apply to rolled steels, forgings, castings used for the manufacture of offshore mooring chain and accessories.

2. Rolled steel bars

(1) Steel manufacture

(A) The steels are to be manufactured by basic oxygen, electric furnace or such other process as may be specially approved.

(B) The austenitic grain size measured in accordance with KS D 0205 or other international rec-

ognised standards is to be 6 or finer.

(C) Steel for bars intended for R 4S and R 5 chain is to be vacuum degassed.

(D) For R 4S and R 5 the following information is to be supplied by the bar manufacturer to the mooring chain manufacturer and the results included in the chain documentation :

(a) Each heat is to be examined for non-metallic inclusions. The level of micro inclusions is to be quantified and assessed; to be sure inclusion levels are acceptable for the final product.

(b)

(c)

A sample from each heat is to be macro etched to be sure there is no injurious segre- gation or porosity.

Jominy hardenability data in accordance with KS D 0206 or other international recog- nised standards is to be supplied with each heat.

(2) Steel manufacture

The approval will normally be limited up to the maximum diameter equal to that of the chain diameter tested. the rolling reduction ratio is to be recorded and is to be at least 5:1. the roll- ing reduction ratio used in production can be higher, but should not be lower than that qualified.

(3) Deoxidation practice and chemical composition

(A) All steels are to be killed and fine grain treated. The chemical composition of ladle samples of each heat is to be determined by the steel maker and is to comply with the approved specification.

(B) The steelmaker is to submit a specification of the chemical composition of the bar material, which must be approved by the Society and by the chain manufacturer. For Grade R 4, R 4S and R 5 chain the steel should contain a minimum of 0.20 % molybdenum.

(4) Mechanical properties

(A) The mechanical properties of chain bars are to comply with the requirements given in

Table 1.

(B) Hydrogen embrittlement test is to be carried out in accordance with the following procedure:

![]()

(a) One tensile test specimen is to be tested within max. 3 hours after machining. (for 14 mm diameter specimen, the time limit is 1.5 hours) Alternatively, tensile test specimen

![]()

may be cooled to -60 immediately after machining and kept at that temperature for a period of max. 5 days.

(b)

(c)

(d)

The other specimen is to be tested after baking at 250 for 4 hours. (for 14 mm di- ameter specimen, the time limit is 2 hours)

A slow strain rate not exceed 0.0003S-1 as far as practicable is used during the entire

test, (This is approximately 10 minutes for the 20 mm diameter specimen) and tensile strength, elongation and reduction of area are to be measured.

The test result is to comply with the following formula.

Z(1) / Z(2) ≥ 0.85

Z(1) is the reduction of area measured by the test specified in (B) (a) Z(2) is the reduction of area measured by the test specified in (B) (b)

![]()

Guidance Relating to the Rules for the Classification of Steel Ships 2015 99

![]()

![]()

![]()

![]()

![]()

Table 1 Mechanical Properties of offshore mooring chain and accessories

Grade | Tensile test | Impact test(1) | ||||||||

Yield strength | Tensile strength ( )(2) | Elongation(%) ( ) | Reduction of area (%) | Test temp | Average absorbed energy (J) | |||||

RSBCR 3 | 410 | min. | 690 min. | 17 | min. | 50 | min. | -20(3) | 40 | min.(3) |

RSBCR 3S | 490 | min. | 770 min. | 15 | min. | 50 | min. | -20(3) | 45 | min.(3) |

RSBCR 4 | 580 | min. | 860 min. | 12 | min. | 50 | min. | -20 | 50 | min. |

RSBCR 4S | 700 | min. | 960 min. | 12 | min. | 50 | min. | -20 | 56 | min. |

RSBCR 5 | 760 | min. | 1000 min. | 12 | min. | 50 | min. | -20 | 58 | min. |

NOTES: (1) When the absorbed energy of two or more test specimens among a set of test specimens is less in val- ue than the specified average absorbed energy or when the absorbed energy of a single test specimen is less in value than 70 % of the specified average absorbed energy, the test is considered to have failed. (2) The yield ratio (the aim value of yield to tensile ratio) for grade R 3, R 3S, or R 4 is to be maximum 0.92. (3) Impact test of grade R 3 and R 3S may be carried out at the temperature of 0 where approved by the Society. In this case, minimum mean absorbed energy is to be not less than 60J for grade R 3 and 65J for grade R 3S. (4) Reduction of area of cast steel is to be for Grades R 3 and R 3S : min. 40 %, for R 4, R 4S and R 5 : min. 35 %. (5) Aim maximum hardness for R 4S is HB330 and R 5 HB340. | ||||||||||

![]()

(5) Selection of test sample

Bars of the same nominal diameter are to be presented for test in batches of 50 tonnes or frac- tion thereof from the same heat. Test specimens are to be taken from material heat treated in the same manner as intended for the finished chain.

(6) Test specimens

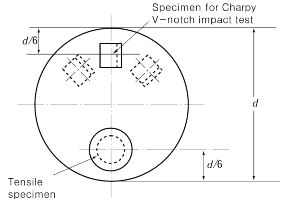

(A) For all grades, one tensile and three Charpy V-notch specimens are to be taken from each sample selected.

(B) For grades R 3S, R 4, R 4S and R 5 in addition to the test specimen required by (A), two tensile test specimens having a diameter of 20 mm in principle, are to be taken for the hy-

drogen embrittlement test. (Consideration will be given to a diameter of 14 mm with the Society's approval.) In this case, test specimen is to be taken from the central region of

bar (a)

(b)

materials heat-treated in the same manner as (a) or (b).

In case of continuous casting, test samples representing both the beginning and the end of the charge(except the mixed zone of the charge) shall be taken.

In case of ingot casting test samples representing two different ingots shall be taken.

(C) The test specimens are to be taken with their longitudinal axis parallel to the final direction of rolling.

(D) The tensile and impact test specimens are to be taken from the test sample in the longi-

tudinal direction at a position. (See Fig 1)

(E) The longitudinal axis

each test specimen.

depth of 1/6 diameter from the surface or as close as possible to this

of the notch is to correspond approximately to the radial direction of

![]()

100 Guidance Relating to the Rules for the Classification of Steel Ships 2015

![]()

Fig 1 Location of test specimens

(7) Surface inspection, non-destructive inspection and verification of dimensions

(A) Non-destructive examination is to be performed in accordance with recognized standards sub- ject to the approval by the Society. Non-destructive examination procedures, together with rejection/acceptance criteria are to be submitted to the Classification Society.

(B) Non-destructive examination operators are to have the qualification given in Annex 2-7, 1

(4) (a) of this guidance in the method of non-destructive examination.

(C) Surface inspection for all grades is to be carried out and it is to be confirmed that there are no harmful defects.

(D) 100 percent of material intended for either chain or fittings are subjected to ultrasonic ex- amination at an appropriate stage of the manufacture and it is to be confirmed that there

are no harmful defects.

(E) For all grades, 100 percent of round bars for chains is to be examined by magnetic particle or eddy current methods and it is to be confirmed by magnetic particle or eddy current methods and it is to be confirmed that there are no harmful defects. Provided that their depth is not greater than 1 % of the bar diameter longitudinal discontinuities may be re- moved by grinding and blending to a smooth contour.

(F) Notwithstanding the requirements of (D) and (E), the frequency of non-destructive inspection may be reduced where the quality control conditions of the manufacturer are satisfactorily met.

(G) The diameter and roundness specified in Table 2.

of all grades of chain bars are to be within the tolerances

Table 2 Dimensional tolerance

Nominal Diameter (mm) | Tolerance on diameter (mm) | Tolerance on roundness (d max - d min) (mm) (1) |

less than 25 | -0, +1.0 | 0.6 max. |

25 ~ 35 | -0, +1.2 | 0.8 max. |

36 ~ 50 | -0, +1.6 | 1.1 max. |

51 ~ 80 | -0, +2.0 | 1.50 max. |

81 ~ 100 | -0, +2.6 | 1.95 max. |

101 ~ 120 | -0, +3.0 | 2.25 max. |

121 ~ 160 | -0, +4.0 | 3.00 max. |

161 ~ 210 | -0, +5.0 | 4.00 max. |

NOTES: (1) d max and d min mean the maximum and minimum diameter of a round bar. | ||

![]()

Guidance Relating to the Rules for the Classification of Steel Ships 2015 101

![]()

(8) Marking

Each bar is to be stamped with the steel grade designation and the charge number 9 or a code indicating the charge number) on one of the end surfaces. Other marking methods may be ac- cepted with the Society's approval.

3. Forged steel

(1) Manufacture

(A) Forged steels used for the manufacture of accessories must be in compliance with approved specifications and the submitted test reports by the Society.

(B) Steel is to be manufactured by basic oxygen, electric furnace or such other process as may be specially approved.

(C) The austenitic grain size measured in accordance with KS D 0205 or other international rec-

ognised standards is to be 6 or finer.

(D) Steel for forgings intended for R 4S and R 5 chain is to be vacuum degassed.

(F) For steel intended for R 4S and R 5 accessories the following information is to be supplied by the steel manufacturer to the mooring accessory manufacturer and the results included in the accessory documentation :

(a) Each heat is to be examined for non-metallic inclusions. The level of micro inclusions is to be quantified and assessed; to be sure inclusion levels are acceptable for the final product.

(b)

(c)

A sample from each heat is to be macro etched to be sure there is no injurious segre- gation or porosity.

Jominy hardenability data in accordance with KS D 0206 or other international recog-

nised standards is to be supplied with each heat.

(2) Steel manufacture

For forgings, the forging reduction ratio, used in the qualification tests, from cast ingot/slab to

gorged component is to be recorded. The forging reduction ratio used in production can be higher, but should not be lower than that qualified.

(3) Deoxidation practice and chemical composition

(A) All steels are to be killed and fine grain treated. The chemical composition of ladle samples of each heat is to be determined by the steel maker and is to comply with the approved specification.

(B) The forge is to submit a specification of the chemical composition of the forged material, which must be approved by the Society. For Grade R 4, R 4S and R 5 chain the steel should contain a minimum of 0.20 % molybdenum.

(4) Heat treatment

Finished forgings are to be properly heat treated in compliance with specifications submitted and approved.

(5) Mechanical properties

The mechanical properties of each grade are to comply with the requirements given in Table 1.

(6) Test specimens

(A) For test sampling, forgings of similar dimensions(diameters do net differ by more than 25 mm) originating from the same heat treatment charge and the same heat of steel are to be combined into one test unit.

(B) One tensile test specimen and one set (3 pieces) of impact test specimens are to be taken from the test sample.

(C) The location of the test specimens is to comply with Fig 1.

(7) Surface and non-destructive inspection

(A) Surface inspection for all grades is to be carried out and it is to be confirmed that there are no harmful defects.

(B) Non-destructive examination is to be performed in accordance with recognized standards sub-

ject to the approval by the Society. Non-destructive examination procedures, together with rejection/acceptance criteria are to be submitted to the Classification Society.

(C) Non-destructive examination operators are to have the qualification given in Annex 2-7, 1

(4) (a) of this guidance in the method of non-destructive examination.

(D) Surface inspection for all grades is to be carried out and it is to be confirmed that there

are no harmful defects.

(8) Marking

Marking of forgings is to be in accordance with 2 (8).

![]()

102 Guidance Relating to the Rules for the Classification of Steel Ships 2015

![]()

4. Steel castings for chains

(1) Manufacture

(A) Cast steels used for the manufacture of accessories must be in compliance with approved specifications and the submitted test reports by the Society.

(B) Steel is to be manufactured by basic oxygen, electric furnace or such other process as may be specially approved.

(C) The austenitic grain size measured in accordance with KS D 0205 or other international rec-

ognised standards is to be 6 or finer.

(D) Steel for castings intended for R 4S and R 5 chain is to be vacuum degassed.

(E) For steel intended for R 4S and R 5 accessories the following information is to be obtained

and the results included in the accessory documentation :

(a) Each heat is to be examined for non-metallic inclusions. The level of micro inclusions is to be quantified and assessed; to be sure inclusion levels are acceptable for the final

product.

(b)

(c)

A sample from each heat is to be macro etched to be sure there is no injurious segre- gation or porosity.

Jominy hardenability data in accordance with KS D 0206 or other international recog-

nised standards is to be supplied with each heat.

(2) Deoxidation practice and chemical composition

(A) All steels are to be killed and fine grain treated. The chemical composition of ladle samples of each heat is to be determined by the steel maker and is to comply with the approved

specification.

(B) The foundries is to submit a specification of the chemical composition of the cast material, which must be approved by the Society. For Grade R 4, R 4S and R 5 chain the steel should contain a minimum of 0.20 % molybdenum.

(3) Heat treatment

All castings are to be properly heat treated in compliance with specifications submitted and ap- proved by the Society.

(4) Mechanical properties

The mechanical properties of each grade are to comply with the requirements given in Table 1.

(5) Test specimens

(A) For test sampling, castings of similar dimensions originating from the same heat treatment charge and the same heat of steel are to be combined into one test unit.

(B) One tensile test specimen and one set (3 pieces) of impact test specimens are to be taken

from the test sample.

(C) The location of the test specimens is to comply with Fig 1.

(6) Surface and non-destructive inspection

(A) Surface inspection for all grades is to be carried out and it is to be confirmed that there are no harmful defects.

(B) Non-destructive examination is to be performed in accordance with recognized standards sub-

ject to the approval by the Society. Non-destructive examination procedures, together with rejection/acceptance criteria are to be submitted to the Classification Society.

(C) Non-destructive examination operators are to have the qualification given in Annex 2-7, 1

(4) (a) of this guidance in the method of non-destructive examination.

(D) The castings are to be subjected to 100 percent ultrasonic examination in compliance with the standard submitted and approved.

(7) Marking

Marking of forgings is to be in accordance with 2 (8).

5. Materials for studs

(1) Studs intended for stud link chain cable are to be made of steel corresponding to that of the chain or in compliance with specifications submitted and approved.

(2) The carbon content should not exceed 0.25 percent if the studs are to be welded in place. ![]()

![]()

Guidance Relating to the Rules for the Classification of Steel Ships 2015 103

Rules for the Classification of Steel Ships

Guidance Relating to the Rules for the Classification of Steel Ships

![]()