< Previous | Contents | Next >

Section 7 Copper and Copper Alloy

701. Copper and copper alloy pipes and tubes

1. Application

(1) The requirements are to apply to the copper and copper alloy pipes and tubes.

(2) Copper and copper alloy pipes and tubes are to comply with the requirements in K S D 5301 or equivalent thereto.

(3) Copper and copper alloy pipes and tubes having characteristics differing from those specified in

701. are to comply with the requirements in 101. 2.

2. Kinds

Copper and copper alloy pipes and tubes are classified as specified in Table 2.1.92.

Table 2.1.92 Kinds and Grades

Kinds | Grades | ||||||||

Copper pipes and tubes. | Phosphorus deoxidized copper seamless pipes and tubes | C | 1201, | C | 1220 | ||||

Copper alloy pipes and tubes | Brass seamless pipes and tubes | C | 2600, | C | 2700, C 2800 | ||||

Brass seamless pipes and tubes for condenser | C | 4430, | C | 6870, | C | 6871, | C | 6872 | |

Cupro-nickel seamless pipes and tubes for condenser | C | 7060, | C | 7100, | C | 7150 | |||

3. Mechanical properties

The mechanical properties of copper quirements given in Table 2.1.93.

and copper alloy pipes and tubes are to comply with the re-

![]()

![]()

![]()

Table 2.1.93 Mechanical Properties

Kinds | Grade | Tensile test(1) | |

Tensile strength (N mm ) | Elongation ( ) | ||

Phosphorus deoxidized copper seamless pipes and tubes. | C 1201, C 1220 | 206 min. | 40 min. |

Brass seamless pipes and tubes | C 2600 | 275 min. | 45 min. |

C 2700 | 294 min. | 40 min. | |

C 2800 | 314 min. | 35 min. | |

Brass seamless pipes and tubes for condenser | C 4430 | 314 min. | 30 min. |

C 6870, C 6871, C 6872 | 373 min.(2) | 40 min. | |

353 min.(3) | 40 min. | ||

Cupro-nickel seamless pipes and tubes for condenser | C 7060 | 275 min. | 30 min. |

C 7100 | 314 min. | 30 min. | |

C 7150 | 363 min. | 30 min. | |

NOTES : (1) These properties are a measure of the mechanical quality of the metal in annealed condition. (2) It is applicable to those having 5 mm and up to 50 mm in outside diameter. (3) It is applicable to those having over 50 mm up to 200 mm in outside diameter. | |||

![]()

4. Testing and inspection

Testing and inspection of pipes and tubes are to com ply with the requirements specified in K S D 5301. Those subjected to the maximum working pressure not exceeding 1 M P a may not require the presence of the Society"s Surveyor.

5. Marking

Copper and copper alloy pipes and tubes which have satisfactorily complied with the required tests are to be marked with the identification mark in accordance with the requirements in 110.

702. Copper alloy castings

1. Application

![]()

![]()

(1) These requirements are to apply to the copper alloy castings to be used for propellers and pro- peller blades (hereinafter referred to as "propeller castings"). Also, upon special consideration of the Society, these requirements may also be applied for the repair and inspection of propellers becoming damaged during service. See Guidance

(2) Copper alloy castings to be used for important parts differing from those specified in 702. are to comply with the requirements of KS or equivalent thereto. The tests and inspections need in general to be made in the presence of the Surveyor where special requirements are given in connection with the design.

(3) Copper alloy castings characteristics differing from those specified in 702. are to comply with the requirements in 101. 2.

2. Kinds Propeller castings are classified as specified in Table 2.1.94.

Table 2.1.94 Kinds and Grades

Kinds | Grade |

High strength brass casting, Grade 1 | CU 1 |

High strength brass casting, Grade 2 | CU 2 |

Aluminium bronze casting, Grade 3 | CU 3 |

Aluminium bronze casting, Grade 4 | CU 4 |

3. Moulding and casting

(1) The pouring must be carried out into dried moulds using degassed liquid metal.

(2) The pouring is to be controlled as to avoid turbulences of flow. Special devices and/or proce- dures must prevent slag flowing into the mould.

(3) Subsequent stress relieving heat treatment may be performed to reduce the residual stresses. For

this purpose, the manufacturer shall submit a specification containing the details of the heat treatment to the Society for approval. The stress relieving temperatures and holding times should

be in accordance with the Guidance relating

Guidance![]()

4. Chemical composition

![]()

to the Rules specified by the Society. See

(1) The chemical composition of propeller castings is to comply with the requirements given in

Table 2.1.95.

![]()

Table 2.1.95 Chemical Composition (%)

Grade | Cu | Al | Mn | Zn | Fe | Sn | Ni | Pb |

C U 1 | 52~62 | 0.5~3.0 | 0.5~4.0 | 35~40 | 0.5~2.5 | 1.5 max | 1.0 max. | 0.5 max. |

C U 2 | 50~57 | 0.5~2.0 | 1.0~4.0 | 33~38 | 0.5~2.5 | 1.5 max | 3.0~8.0 | 0.5 max. |

C U 3 | 77~82 | 7.0~11.0 | 0.5~4.0 | 1.0 max. | 2.0~6.0 | 0.1 max. | 3.0~6.0 | 0.03 max. |

C U 4 | 70~80 | 6.5~9.0 | 8.0~20.0 | 6.0 max. | 2.0~5.0 | 1.0 max. | 1.5~3.0 | 1.5 max. |

![]()

(2) For C U 1 and C U 2, it is also to comply with the followings:

(a) The zinc equivalent as specified below is not to exceed 45 %

Zinc equivalent = ![]()

Where A : Sn + 5A l - 0.5M n - 0.1F e - 2.3N i (%)

(b) Each tensile test specimen is to be examined metalographically, and the proportion of al- pha-phase determined from an average of five counts is not to be less than 25 %.

5. Mechanical properties

(1) The mechanical properties of copper propeller casting are to comply with the requirements given in Table 2.1.96.

However, the requirements specified in this Table apply to specimens cut from separately cast

![]()

samples, where specimens cut from propeller appropriate by the Society. See Guidance![]()

![]()

![]()

![]()

![]()

![]()

Table 2.1.96 Mechanical Properties

casting itself, the requirements are to be deemed

Grade | Yield strength(1) (N mm ) | Tensile strength (N mm ) | Elongation (%) ( ) |

CU 1 | 175 min. | 440 min. | 20 min. |

CU 2 | 175 min. | 440 min. | 20 min. |

CU 3 | 245 min. | 590 min. | 16 min. |

CU 4 | 275 min. | 630 min. | 18 min. |

NOTE: (1) Yield strength is measured as 0.2 % proof stress and is applicable to the case which is spe- cially required considering the design by the Society. See Guidance (2) As for the materials of the propellers which used for the ship strengthened for navigation in ice, the elongation of the materials used is not to be less than 19 % for R14A test specimen specified in Pt 2, Ch 1 and absorbed energy for the Charpy V notch impact test is not to be less than 21 J at -10°C | |||

![]()

![]()

6. Selection of Test Samples and Specimens

(1) Generally, the specimens shall be taken from separately cast sample pieces. The test samples shall be cast in moulds made of the same material as the mould for the propeller and they must be cooled down under the same conditions as the propeller. If propellers are subjected to a heat treatment, the test samples are to be heat treated together with them.

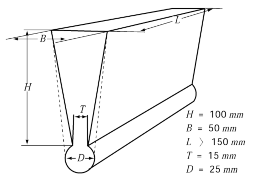

(2) The shapes and dimensions of the test samples are to comply with those given in Fig 2.1.27

The shape given by the dotted lines shown in the figure, however, may be acceptable.

![]()

Fig 2.1.27 shapes and dimensions of the Test Samples

![]()

(3) One tensile test specimen is to be taken from each casting when integral test samples are pro- vided and one tensile test specimen is to be taken from each ladle when separately-cast test samples are provided.

(4) For determining the proportion of alpha phase of alloy types C U 1 and C U 2. at least one specimen shall be taken from each heat. However tensile test specimen can be substitute for.

(5) When integral test samples are provided, the test samples shall be located on the blades in an

area lying between 0,5 to 0,6 R (where R is the radius of the propeller). The test sample mate- rial must be removed from the casting by non thermal procedures.

7. Surface and dimension Inspection

(1) Propeller casting is to be subjected to a comprehensive visual inspection by the Surveyor at fi- nal process and other proper processing stages if necessary.

(2) The dimensions are to be checked by the manufacturer and the report on the dimensional in-

![]()

spection is to be handed over to the Surveyor, who may require checks to be made in his presence. Where straightening of a bent blade is carried out, the procedure for the straightening is to be in accordance with the Guidance relating to Rules specified by the Society. See

![]()

Guidance

(3) The Surveyor may be require areas to be etched (e.g. by iron chloride) for the purpose of in- vestigating weld repairs.

8. Quality

All castings must have a workman like finish and must be free from defects liable to impair their use. Minor casting defects which may still be visible after machining such as small sand and slag inclusions, small cold shuts and scabs shall be trimmed off by the manufacturer.

9. Non-destructive inspection

![]()

![]()

(1) The important parts of propeller castings are to be subjected to the liquid penetrant test in ac- cordance with the Guidance relating to Rules specified by the Society. See Guidance

(2) The division of severity zones of propeller casting is to be in accordance with the Guidance re-

lating to Rules specified by the Society.

(3) Where serious doubts exist that the castings

are not free from internal defects, further non-

destructive inspections

and/or ultrasonic tests.

are to be carried out

For this purpose, the

upon request of the Surveyor, e.g. radiographic

acceptance criteria are to be agreed between the

manufacturer and the Society in accordance with a recognized standard.

(4) All defects requiring welding repair on the propeller castings are to be documented preferably on drawings or special sketches showing their dimensions and locations. Furthermore, the in-

spection procedure is to be reported. The documentation is to be presented to the Surveyor prior to any repair weldings will be carried out.

10. Repair of defects

(1) In the event of finding defects in the propeller castings, the defects may be removed by grind- ing, etc. After removing the defects, liquid penetrant tests are to be carried out to ensure that all defects have been completely removed.

(2) Where the propeller castings from which defects where removed are used in that condition or after repaired by welding, the propeller castings are to be approved by the Surveyor.

(3) After weld repairs, the portions repaired by welding are to be subjected to the stress-relieving treatments.

(4) It is to be confirmed that the portions repaired by welding are free from harmful defects by the non-destructive inspections such as liquid penetrant test, etc.

(5) The repair welding procedures are to have prior approval of the Surveyor in accordance with the

![]()

![]()

Guidance relating to the Rules specified by the Society. See Guidance

11. Retest procedure

Where the results of tensile tests fail to meet the requirements, additional test may be carried out in accordance with the requirements of 109.

12. Marking

(1) Prior to final inspection by the Surveyor each casting shall be marked by the manufacturer at least with the following symbols:

(a) Grade of cast material or corresponding abbreviated designation

![]()

(b)

(c)

(d)

(e)

(f)

(g)

(h)

(i)

Manufacturer’s mark

Heat number, casting number or another mark enabling the manufacturing process to be traced back

Specimen number

Date of final inspection

Number of the Society’s test certificate

Ice class symbol, where applicable Skew angle for high skew propellers.

Manufacturer's certificate

(2) For each propeller the manufacturer must supply to the Surveyor a certificate containing lowing details:

the fol-

(a)

(b)

(c)

(d)

(e)

(f)

(g)

(h)

Purchaser and order number Shipbuilding project number, if known

Description of the casting with drawing number

Diameter, number of blades, pitch, direction of turning Grade of alloy and chemical composition of each heat

Heat or casting number Final weight

Results of non-destructive tests and details of test procedure where applicable

(i)

(j)

Portion of alpha-structure for CU 1 and

Results of the mechanical tests

CU 2 alloys

(k) Casting identification No.

(l)

Skew angle for high skew propellers

![]()