< Previous | Contents | Next >

Section 4 Anchors

401. Applications

1. The anchors on yacht dealt with in this chapter are to comply with of equivalent quality.

2. The manufacturers certificate of conformance shall be supplied for the

(1) anchor

(2) anchor chain cable / wire rope

(3) windlass

the requirements below or be following equipment :

402. General

1. Anchor types

(1) H.H.P. (high holding power) anchor

(2) S.H.H.P. (super high holding power) anchor, ordinary stockless bow anchor or other types of anchors may be specially considered.

2. When two anchors are chosen, the mass of one anchor is not to be less than 60 % of the value in Table 4.2.2 provided the total mass of anchors is not less than the requirement to one anchor. The mass of the head of the anchor is not to be less than 60 % of the table value.

3. Anchors made from stainless steel is permitted provided the mass and the strength is not less than required for steel.

403. Materials

Materials used for anchors are to comply

Steel Ships.

with

Pt 4, Ch

8 of Rules for the Classification of

404. Drop and hammering tests

Drop and hammering tests are to comply

Steel Ships.

with

Pt 4, Ch

8 of Rules for the Classification of

405. Proof tests

![]()

Proof tests of anchor are to comply with Pt 4, Ch 8 of Rules for the Classification of Steel Ships. The proof test load, however, for hight holding power anchor is to be the load specified for an ordinary anchor of which the mass is equal to 2 times the actual total mass of a high hold- ing power anchor.

![]()

![]()

Table 4.2.2 Bower Anchors, Chain Cables and Ropes

Equip ment letter | Equipment number | Bower anchors | Stud link chain cable for bower anchors | Mooring line | |||||||||

Mass ( ) | Total Length (mm ) | Diameter | Breaking load (kN) | Num ber | Length (m ) | Breaking load (kN) | |||||||

Exce- eding | Not exce- eding | Num ber | HHP | SHHP | Grade 1 | Grade 2 | Grade 3 | ||||||

HS1 | 30 | 40 | 1 | 93 | 62 | 115 | 12.5 | 66 | 2 | 40 | 32 | ||

HS2 | 40 | 50 | 1 | 119 | 79 | 115 | 12.5 | 66 | 2 | 40 | 32 | ||

HS3 | 50 | 60 | 1 | 146 | 97 | 130 | 14 | 12.5 | 82 | 3 | 40 | 34 | |

HS4 | 60 | 70 | 1 | 171 | 114 | 130 | 14 | 12.5 | 82 | 3 | 40 | 34 | |

HS5 | 70 | 80 | 1 | 198 | 138 | 130 | 16 | 14 | 107 | 3 | 50 | 37 | |

HS6 | 80 | 90 | 1 | 224 | 149 | 130 | 16 | 14 | 107 | 3 | 50 | 37 | |

HS7 | 90 | 100 | 1 | 251 | 167 | 150 | 17.5 | 16 | 127 | 3 | 55 | 39 | |

HS8 | 100 | 110 | 1 | 276 | 184 | 150 | 17.5 | 16 | 127 | 3 | 55 | 39 | |

HS9 | 110 | 120 | 1 | 303 | 202 | 150 | 19 | 17.5 | 150 | 3 | 55 | 44 | |

HS10 | 120 | 130 | 1 | 329 | 219 | 150 | 19 | 17.5 | 150 | 3 | 55 | 44 | |

HS11 | 130 | 140 | 1 | 356 | 237 | 165 | 20.5 | 17.5 | 175 | 3 | 60 | 49 | |

HS12 | 140 | 150 | 1 | 383 | 255 | 165 | 20.5 | 17.5 | 175 | 3 | 60 | 49 | |

HS13 | 150 | 160 | 1 | 408 | 272 | 165 | 22 | 19 | 200 | 3 | 60 | 54 | |

HS14 | 160 | 175 | 1 | 441 | 294 | 165 | 22 | 19 | 200 | 3 | 60 | 54 | |

HS15 | 175 | 190 | 1 | 480 | 320 | 180 | 24.5 | 20.5 | 237 | 3 | 60 | 59 | |

HS16 | 190 | 205 | 1 | 521 | 347 | 180 | 24.5 | 20.5 | 237 | 3 | 60 | 59 | |

HS17 | 205 | 220 | 1 | 560 | 373 | 180 | 26 | 22 | 20.5 | 278 | 4 | 60 | 64 |

HS18 | 220 | 240 | 1 | 606 | 404 | 180 | 26 | 22 | 20.5 | 278 | 4 | 60 | 64 |

HS19 | 240 | 260 | 1 | 659 | 439 | 200 | 28 | 24 | 22 | 321 | 4 | 60 | 69 |

HS20 | 260 | 280 | 1 | 711 | 474 | 200 | 28 | 24 | 22 | 321 | 4 | 60 | 69 |

HS21 | 280 | 300 | 1 | 764 | 509 | 215 | 30 | 26 | 24 | 368 | 4 | 70 | 74 |

HS22 | 300 | 320 | 1 | 816 | 544 | 215 | 30 | 26 | 24 | 368 | 4 | 70 | 74 |

HS23 | 320 | 340 | 1 | 869 | 579 | 215 | 32 | 28 | 24 | 417 | 4 | 70 | 78 |

HS24 | 340 | 360 | 1 | 926 | 617 | 215 | 32 | 28 | 24 | 417 | 4 | 70 | 78 |

HS25 | 360 | 380 | 1 | 974 | 649 | 230 | 34 | 30 | 26 | 468 | 4 | 70 | 88 |

HS26 | 380 | 400 | 1 | 1028 | 685 | 230 | 34 | 30 | 26 | 468 | 4 | 70 | 88 |

HS27 | 400 | 425 | 1 | 1086 | 724 | 230 | 36 | 32 | 28 | 523 | 4 | 70 | 98 |

HS28 | 425 | 450 | 1 | 1152 | 768 | 230 | 36 | 32 | 28 | 523 | 4 | 70 | 98 |

HS29 | 450 | 475 | 1 | 1226 | 817 | 230 | 36 | 32 | 28 | 523 | 4 | 70 | 108 |

HS30 | 475 | 500 | 1 | 1284 | 856 | 230 | 38 | 34 | 30 | 581 | 4 | 70 | 108 |

To be continued next page. | |||||||||||||

![]()

Table 4.2.2 Bower Anchors, Chain Cables and Ropes (continued)

Equip ment letter | Equipment number | Bower anchors | Stud link chain cable for bower anchors | Mooring line | |||||||||

Mass ( ) | Total Length (mm ) | Diameter | Breaking load (kN) | Num ber | Length (m ) | Breaking load (kN) | |||||||

Exce- eding | Not exce- eding | Num ber | HHP | SHHP | Grade 1 | Grade 2 | Grade 3 | ||||||

HS31 | 500 | 550 | 1 | 1403 | 935 | 248 | 40 | 34 | 30 | 640 | 4 | 80 | 123 |

HS32 | 550 | 600 | 1 | 1535 | 1024 | 264 | 42 | 36 | 32 | 703 | 4 | 80 | 132 |

HS33 | 600 | 660 | 1 | 1694 | 1129 | 264 | 44 | 38 | 34 | 769 | 4 | 80 | 147 |

HS34 | 660 | 720 | 1 | 1853 | 1235 | 264 | 46 | 40 | 36 | 837 | 4 | 80 | 157 |

HS35 | 720 | 780 | 1 | 2012 | 1341 | 281 | 48 | 42 | 36 | 908 | 4 | 85 | 172 |

HS36 | 780 | 840 | 1 | 2171 | 1447 | 281 | 50 | 44 | 38 | 981 | 4 | 85 | 186 |

HS37 | 840 | 910 | 1 | 2329 | 1553 | 281 | 52 | 46 | 40 | 1060 | 4 | 85 | 201 |

HS38 | 910 | 980 | 1 | 2515 | 1676 | 297 | 54 | 48 | 42 | 1140 | 4 | 85 | 216 |

HS39 | 980 | 1060 | 1 | 2700 | 1800 | 297 | 56 | 50 | 44 | 1220 | 4 | 90 | 230 |

HS40 | 1060 | 1140 | 1 | 2912 | 1941 | 297 | 58 | 50 | 46 | 1290 | 4 | 90 | 250 |

HS41 | 1140 | 1220 | 1 | 3124 | 2082 | 314 | 60 | 52 | 46 | 1380 | 4 | 90 | 270 |

HS42 | 1220 | 1300 | 1 | 3335 | 2224 | 314 | 62 | 54 | 48 | 1470 | 4 | 90 | 284 |

HS43 | 1300 | 1390 | 1 | 3574 | 2382 | 314 | 64 | 56 | 50 | 1560 | 4 | 90 | 309 |

HS44 | 1390 | 1480 | 1 | 3812 | 2541 | 330 | 66 | 58 | 50 | 1660 | 5 | 90 | 324 |

HS45 | 1480 | 1570 | 1 | 4050 | 2700 | 330 | 68 | 60 | 52 | 1750 | 5 | 95 | 324 |

HS46 | 1570 | 1670 | 1 | 4315 | 2876 | 330 | 70 | 62 | 54 | 1840 | 5 | 95 | 333 |

HS47 | 1670 | 1790 | 1 | 4632 | 3088 | 347 | 73 | 64 | 56 | 1990 | 5 | 95 | 353 |

HS48 | 1790 | 1930 | 1 | 4950 | 3300 | 347 | 76 | 66 | 58 | 2150 | 5 | 95 | 378 |

NOTE : (1) Chain cable may be substituted by wire or synthetic fibre rope, according to 501. | |||||||||||||

406. Additional requirements for S.H.H.P. anchors

1. S.H.H.P. anchors for which approval is sought, are to be tested by requirements in Guidance for Approval of Manufacturing Process and Type Approval, Etc. to show that they have a hold- ing power per unit of mass at least 4 times that of an ordinary stockless anchor.

2. If approval is sought for a range of anchor sizes, at least two sizes are to be tested. The mass of the larger anchor to be tested is not to be less than 1/10 of that of largest anchor for which ap- proval is sought. The smaller of the two anchors to be tested is to have a mass not less than 1/10 of that of the larger anchor to be tested.

407. Marking

1. Where anchors have satisfactorily passed the tests and inspections, they are to be stamped with the Society's brand in compliance with Pt 4, Ch 8 of Rules for the Classification of Steel Ships.

2. In case of addition to

![]()

high holding power anchors, "SH" is to be stamped in front of the Society's brand in the stamps specified in Par 1.

![]()

408. Danforth anchor

1. For a ship of less than 30 m in length, if Danforth anchor is intended to be provided with special

shaped construction and dimension, the relevant drawings shall be submitted to the be approved before manufacturing.

2. Where the equipment number is calculated in accordance with Pt 3, Ch 1, Sec

Society and to

57, Para 2 of

Ship's Equipment Standards to Korean Ship Safety Act the requirement given in Table 4.2.3. shall be applied for Danforth anchor, Anchor rope, Tow line and Mooring rope. etc.

3. The dimensions of Danforth anchor shall be in accordance with Table 4.2.4, except other Danforth

anchor with different size and construction

Society. ![]()

which shall be appropriate to the requirement of the

Equipment number | Danforth anchor | Lock used for anchor (per an anchor) | Tow line (standards of manila rope) | Mooring rope (standards of manila rope) | ||||||||||

Exceeding | Not exceeding | Number | Masst ( ) | Length ( ) | Diameter (mm ) | |||||||||

Manila rope | Nylon rope | vinyl rope | Chain | Length ( ) | Diameter (mm) | Number | Length ( ) | Diameter (mm) | ||||||

Grade 1 | Grade 2 | |||||||||||||

80 90 105 140 175 | 90 105 140 175 215 | 2 2 2 2 2 | 20 25 30 40 50 | 60 70 80 90 100 | 24 28 32 35 38 | 17 20 22 25 27 | 20 24 27 30 33 | . . . . . | 110 110 110 135 135 | 28 30 32 34 36 | . 1 1 1 1 | . 165 165 165 165 | . 20 20 22 24 | |

215 255 295 390 | 255 295 390 445 | 2 2 2 2 | 60 70 95 125 | 100 110 110 120 | 42 45 50 60 | 30 32 35 42 | 36 38 42 50 | 14 14 16 17.5 | 12.5 12.5 14 16 | 135 135 135 135 | 40 45 50 50 | 1 1 1 1 | 165 165 165 165 | 24 24 32 32 |

Table 4.2.3 Danforth anchor and Rope

kg m

m m

![]()

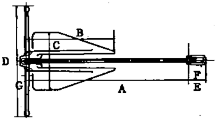

Table 4.2.4 Each Dimension of Danforth anchor

Dimension(mm ) Mass(kg) | A | B | C | D | E | F | G |

20 | 825 | 463 | 361 | 685 | 95 | 18 | 23 |

25 | 890 | 500 | 390 | 740 | 104 | 20 | 25 |

30 | 945 | 565 | 414 | 784 | 109 | 21 | 26 |

40 | 1,049 | 590 | 460 | 872 | 122 | 24 | 29 |

50 | 1,154 | 647 | 506 | 960 | 134 | 26 | 32 |

60 | 1,190 | 668 | 521 | 988 | 137 | 27 | 33 |

75 | 1,280 | 719 | 561 | 1,063 | 149 | 29 | 35 |

100 | 1,400 | 790 | 616 | 1,170 | 163 | 31 | 43 |

120 | 1,500 | 840 | 657 | 1,240 | 174 | 34 | 45 |

A : Anchor Shaft(Shank) Length C : Anchor Arm(p) ↔ Anchor Arm.(s) D : Stock Length E : Anchor Ring(Shackle) Length F : Anchor Ring(Shackle) Dia. G : Stock Dia. | |||||||

![]()