Material and Equipment

Legal and traditional role of classification society, as an autonomous entity, reference is exerting audits, surveys, and approval of marine materials and equipment, and it has been recognized the only solution at the presence of marine industries suppliers, with quality and consistent manner, which remains with classification societies.

One of the most important goals of this society is providing survey and classification services to the owners, industrial entities and producers in the concurrent with economy of time and quality, and utility of services at low cost in comparison with international classification societies while all society’s approved rules and regulations are in conformity with IACS mandates.

When a producing company apart from its own management system for a type of its products or a batch of it products requiring approval or builder of a vessel requesting approval of a particular item to be fitted on its vessel, type test approval can be issued.

The trend and general stage of obtaining the type approval of a particular product and report on test on batch of products are as follows:

- Receiving necessary documents, from producer.

- Review and examination of all received documents.

- Visit and control of products.

- Selection of a produced item and carry out the necessary tests on the basis of relevant standards.

- Review the conclusion of the process and issue the certificate of type approval on confirmation of tests.

- Compiling of application form.

- Standard used for producing and testing process of such products.

- Company’s proformation in the context of production of the same items.

- Documents, calculation and drawings pertinent to product.

- Fabrication process of product and relevant flow chart.

- Report on tests carried out by producer.

- Provision of operation, maintenance and repairs manual pertinent to the product.

This type approval needed when, a producer requiring approval for one or more different products produced in its premises, continuously by receiving this approval, all producing lines to produce unlimited number being confirmed.

Trend and general stages obtaining type approval:

- Receiving documents, from requester.

- Review and verification of all documents.

- Plan and coordination initial auditing in respect to establishing quality management system, structure of the company.

- Inspection of production line and execution of required technical test on products in the basis of pertinent standards.

- Review the result and issue of type approval certificate in case of society confirmation.

- Coordination, and provision of plan for inspection for auditing periodical test on product to maintain validity of the certificate.

- Compile of application form.

- Document, technical drawings, plan, operator instruction, maintenance, repairs manuals.

- Documents related to company structure, including organization charts, management scheme.

- Company profile.

- List of company personnel, comprising of names, training passed by them, certificate & relevant service record.

- List of equipment deployed in process of producing including makers, calibration records associated with calibration certificate.

- List of representations, company affiliated offices and branches (if applicable).

- Standards employed for designe and production.

- Any certification obtained by other relevant administration.

-

Required documents for reviewing quality assurance system:

- Quality system

- instructions & forms of quality assurance including:

-

- Instruction/ procedure quality control.

- Instruction of equipment control.

- Instruction on maintenance, repairs and calibration of equipment.

- Instruction manual for required test related to quality control of products.

- Instruction and forms for reporting quality control matters by said unit.

- Instruction manual for training and assessment of company personnel.

- Instruction related to coding the products.

- Instruction for assessment of suppliers.

- Storage instruction.

- Purchase Instruction.

In general, by considering the level of quality management system, also performance and quality of products, producing process, and … trend and producer to obtain approval would be determined. For example:

- If this is a valid type approval certificate from recognized organization, just receiving relevant documents during the inspection on line of production will be effected.

- Those products which have a valid type approval certificates from recognized organization. Required certificate may be issued on ascertation of record and documents after reviewing the whole documentation and auditing and inspection of production lines.

- in case of holding a type approval certificate for any product, which were produce earlier and the company still maintained its valid quality management system, a type approval certificate may be issued on receiving and proving the required documents and confirmatory inspection of production line.

- Review of document and drawings related to establishing quality management system

- Auditing of the company

- Occasional provision of services

- Review of the documents and issue of certificate

- Periodical auditing, endorsement and extension of the certificates

- Compilation of application form

- Specification of company, organizational chart, management structure, way of launching quality management within its organization.

- Review the result and issue of type approval certificate in case of society confirmation.

- Coordination, and provision of plan for inspection for auditing periodical test on product to maintain validity of the certificate.

- Compile of application form

- Document, technical drawings, plan, operator instruction, maintenance, repairs manuals

- Documents related to company structure, including organization charts, management scheme

- List of company personnel, comprising of names, training passed by them, certificate & relevant service recor

- List of equipment deployed in process of producing including makers, calibration records associated with calibration certificate

- List of representations, company affiliated offices and branches (if applicable)

- Standards employed for design and production

- Any certification obtained by other relevant administration

- Quality system documents are as follows:

-

- Quality system

- Instructions and quality control forms including:

-

- Instruction on internal organization periodical quality audit

- Instruction on document control

- Instruction on record of events and functioning reports

- Instruction on service providers (if any)

- Instruction and forms on reporting to company quality control system

- Instruction on training and competency of personnel

- Record of clients comments and actions taken place

For approving the competency of welders, the following measures shall put into effect.:

- Test of welders according to company WPS which is verified by classification society.

- Test shall be effected on the presence of this society expert.

- Test of welders could take place as marked in below table:

| WELD | POSITION |

|---|---|

| Plate - Fillet | 1F, 2F, 3F, 4F |

| Plate - Groove | 1G, 2G, 3G, 4G |

| Pipe - Groove | 1G, 2G, 5G, 6G |

- The cost of all tests, preparation of companies & expert travel cost shall be paid by customers if to be out of main ports.

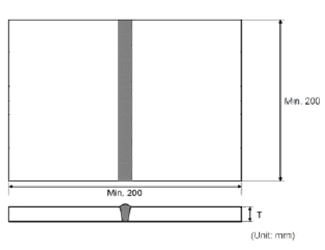

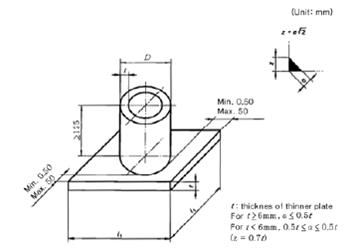

- Minimum dimensions required (mm) for testing of Butt Weld.

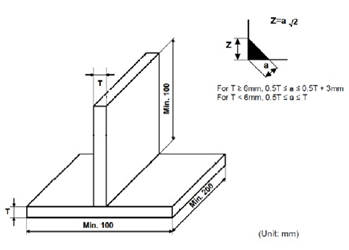

- Minimum dimensions required (mm) for testing of filet Weld.

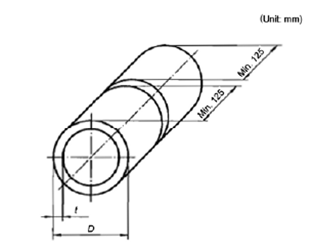

- Minimum dimensions required (mm) for testing of Butt Weld in pipe.

- Minimum dimensions required (mm) for testing of filet Weld in pipe.

Based on routine, Rules & Regulations of classification societies & also Ports & Maritime Organization procedures, all companies which are involved in rendering services to the vessels & marine institutes that are under class of classification societies shall be approved by these societies.

The trend of approval by Iranian Classification Society is as follows:

- Completing the application form

- Initial inspection of shipyard in order to orientation with building, equipment, machinery, labor & working conditions.

- Evaluation of revised document which was rendered by ship yard.

- Planning & coordination in order to internal auditing & assessment ability of company for compliance with requirements & requirements of welding process.

- Issuance approval certificate if successfully complete all phases

- Coordination & submitting program for the next periodical auditing It is worth mentioning that during the above process, practically in order to vessel repairing occasionally & provided comply with pertinent requirements & standards, there will be no interference with required procedures.